Products > Sample Cylinders

Swagelok Sample Cylinders

View design highlights, Swagelok® catalogues, and local FAQs. Learn about the Cylinder Maintenance Program, Grab Sampling Program, sample cylinder assemblies, and more. Tel: 780-437-0640.

Sample Cylinders, Accessories, and Outage Tubes Catalogue

Cylinders for Collecting Gas and Liquid Samples

Scroll below to see some of our sample cylinders, sample cylinder assemblies, and grab sample modules. Want a hand selecting? Please use the green button to message us for details.

.webp)

.webp)

.webp)

.webp)

Our local team offers quick quotes, product selection advice, and daily shipping. If we can help in any way, please message us or call 780-437-0640.

Sampling System Evaluations with Field Advisor Tom Webster

Our team can conduct in-depth analyses of your system, from process tap to analyzer.

Swagelok Edmonton Field Advisor Tom Webster has completed a year-long training and testing regime under experts like Tony Waters—arguably the leading authority on industrial sampling systems—and expanded our capacity for conducting Sampling System Evaluation and Advisory Services (SSEAS). During a Sample System Audit, Tom (and, if needed, a team of peers) examines your systems and identifies steps to boost consistency, reliability, and efficiency.

"SSEAS is a full system evaluation," Tom says. We take a holistic look at the facility and report with recommendations and suggestions on how to improve plant efficiency and safety. We can do wake frequency calculations and time delay calculations, advise on line sizing, and help with sample system design."

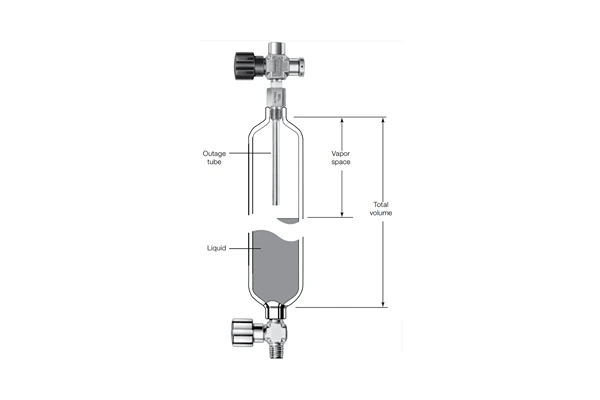

Features for Safe, Efficient Grab Sampling

The reliability of Swagelok's sample cylinders derives from high quality materials, thoughtful design, and extraordinary manufacturing process controls. Let's look at examples:

Switching Valves

.webp)

Grab Sample Valves

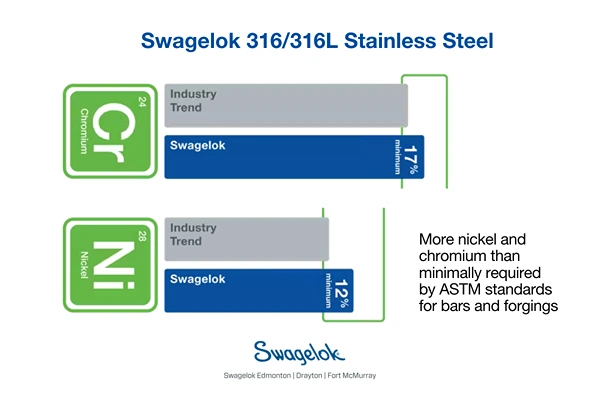

Material Matters

In stainless steels, chromium and nickel are critical for corrosion resistance and ductility. Not all bar stock is the same. Swagelok 316/316L stainless steel tube fittings and instrumentation valves contain more nickel and chromium than minimally required by ASTM standards for bars and forgings.

Cost-Effectively Improve Grab Sampling

We understand what it takes to build safety, ease of use, and reliable performance into grab sampling systems.

Swagelok grab sampling systems satisfy gas and liquid non-slurry sampling service in a consistent, reliable package. The overall approach is to combine expert analysis with rapid configuration of a standard panel design to exact specs. The result is a configurable, local, reliable solution.

To learn more please watch the video and download literature in the next section.

.webp?width=300&height=162&name=Collection%20-%20Grab%20Sampling(300).webp)

Grab Sampling Best Practices Resource Collection

Cylinder Maintenance Program

Every sample cylinder should get inspected and pressure tested at least once a year. We are ready to help.

Damaged or malfunctioning cylinders can present a safety issue for staff, and may compromise the accuracy and integrity of your sampling practices. Regular, proactive sample cylinder maintenance is a must for any sampling-centric operation.

Every sample cylinder should get inspected and pressure tested at least once a year. Even if it's not a must-do by law, looking after cylinders helps keep everyone safe and everything running smoothly.