Share this

The Benefits of API Plan 32 Design/Build for SAGD Facilities or Upgraders

by Thomas Webster on Thu, Jul 22, 2021 @ 09:07 AM

Alberta SAGD operations require carefully controlled fluid pressures, so mechanical seals and seal support systems are critical to their success. The climate and high-viscosity fluids in SAGD can create especially difficult environments for mechanical seals. Fortunately, proper API 682 Seal Plan implementation can protect those seals and ensure safe, reliable operation.

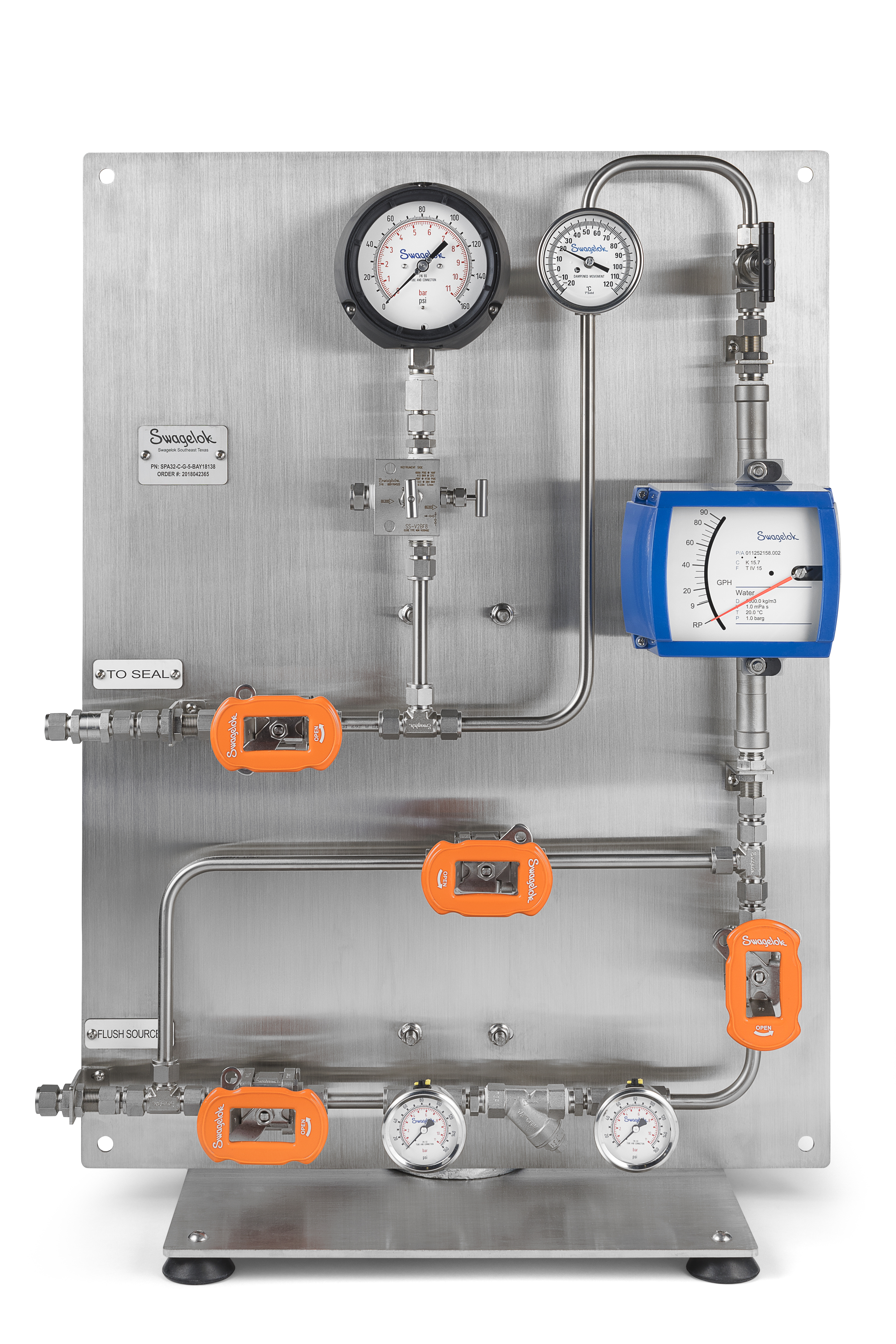

SAGD equipment may require a variety of different API 682 external flush plans. API Plan 32 is one common example. These plans are well-documented, but there is more to successful implementation than just selecting a plan from a catalogue. For total confidence in your API Plan 32 design/build, the best option is to rely on the expertise of an experienced seal support systems supplier.

Below, we’ll look at what Plan 32 is, a few design considerations, and how partnering with an experienced seal support systems supplier for an API Plan 32 design/build ensures you get a system that’s efficient, reliable, and cost-effective.

What Is API Plan 32?

API Plan 32 delivers a clean, external fluid to the seal chamber for flushing and lubrication. This plan is used when the process fluid itself is too corrosive, abrasive, hot, or otherwise unsuitable for lubricating and cooling the seal.

API Plan 32 delivers a clean, external fluid to the seal chamber for flushing and lubrication. This plan is used when the process fluid itself is too corrosive, abrasive, hot, or otherwise unsuitable for lubricating and cooling the seal.

The objective of Plan 32 is to isolate the seal face from the process fluid by injecting the external flush fluid into the seal chamber via a close-clearance throat bushing. Because some flush fluid will enter the system and mix with the process fluid, the fluids must be compatible.

A good API Plan 32 design/build must be tailored to the fluid system. The process fluid, flush fluid, piping, pumps, seals, operating conditions, and many other variables can significantly affect a flush plan’s design. A rigorous design/build process is essential to prevent seal failure and keep SAGD operations running safely and efficiently.

API Plan 32 Design/Build Considerations

When it comes to seal support systems, there is no one-size-fits-all solution. Every component must be carefully designed for the application parameters. For a seal support system to perform optimally in SAGD operations, there are many variables to account for. Below are a few examples of special considerations that may need to be taken during an API Plan 32 design/build:

| Requirement | Design Considerations |

| The external flush source must provide a continuous and reliable flow. | Waterline pressure is variable and can drop below the required seal chamber pressure. The flush system may need an external pump and reservoir to maintain adequate pressure. |

| The flush fluid must be delivered at 15 to 25 psi (1 bar to 1.7 bar) above seal chamber pressure. | The throat bushing clearance must be designed to operate reliably while maintaining pressure at the process temperature. Instrumentation is needed at key locations to monitor pressure. |

| For high-temperature process fluids, the flush fluid temperature must be low enough to cool the seal face. | Ensure the flush source can consistently deliver the required flow and temperature. Existing equipment may need to be retrofitted. |

| The flush fluid must be free of damaging abrasives. | A filtration system and/or bypass loop may be required. |

| The flush fluid must be compatible with the process fluid. | If using a flush fluid other than water, additional configuration to the pump, reservoir, or piping may be required. |

Other custom features may include high-point vents to clear trapped air, low-point drains to purge flush fluids, or bypass loops to provide a continuous supply of flush fluid during maintenance.

There’s a lot to consider when starting an API Plan 32 design/build. Making sure the design fits the application requires both general seal support expertise and a comprehensive understanding of the specific process.

Leave API Plan 32 Design/Build to the Experts

Given time, resources, and the right skills, a SAGD operation that needs Plan 32 installation, replacement, or upgrading might be able to do the job in-house—but there’s a better way. An expert seal support systems supplier can help by designing, building, testing, and delivering a Plan 32 system optimized for your operation.

When beginning an API Plan 32 design/build with Edmonton Valve & Fitting, an experienced Field Advisor first performs an onsite assessment. This assessment allows us to:

- Understand the process details, including fluid characteristics, pump rate, seal design, and facility layout

- Evaluate the source, quality, and reliability of the flush fluid source

- Determine how existing or planned infrastructure will affect the design

A Field Advisor conducts layout support for Plan 32 based on this assessment and provides technical specifications for the customer to review. Upon approval, certified technicians install Plan 32.

By partnering with a seal support system service provider, you ensure your API Plan 32 design/build goes smoothly and every factor is accounted for. You can be confident you’re getting the best possible product while enjoying benefits like:

- Fast, convenient project management

- Cost savings

- Onsite field testing

- Warranty service

In short, it may be possible to take on an API Plan 32 design/build project in-house, but an experienced, local seal support systems supplier can design a high-quality seal support system tailored to your process.

Experienced, Local Field Advisors

At Edmonton Valve & Fitting, we are committed to providing full-service, fluid handling solutions in central and northern Alberta. We earn our customers' trust and confidence by thoroughly understanding their requirements and delivering on time, every time.

We build our API 682-compliant systems locally, so you get what you need quickly. We test all systems thoroughly to validate safety, reliability, and ease of maintenance. All our products are backed by Swagelok’s Limited Lifetime Warranty—one of the strongest in the industry.

When you’re ready, Field Advisors at Edmonton Valve & Fitting can perform an onsite evaluation to understand your process and design/build needs. Our Field Advisors are experts in API 682 implementation for SAGD operations and will make sure you get the seal support solution you need.

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)