Share this

API Plan 32 Troubleshooting in the Field Doesn’t Have to Be a Headache

by Thomas Webster on Thu, Jul 29, 2021 @ 11:07 AM

|

|

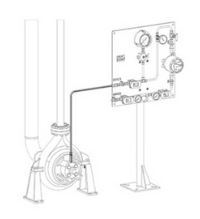

A flush plan is essential to maintain proper lubrication, pressure, and temperature at a mechanical seal face. When the process fluid itself is too aggressive to use as a flush fluid, API Plan 32 protects the seal by injecting water or another external flush fluid into the seal chamber.

API Plan 32 is common in Alberta oil and gas operations because it is simple, reliable, and effective for a wide range of fluid handling applications. However, it’s always possible that something can go wrong—especially in the field. Field Advisors and technicians must be familiar with all aspects of the system so they can respond to problems quickly and complete API Plan 32 troubleshooting to determine their root causes.

Below, we’ll look at common pressure, flow, and temperature problems you might encounter during API Plan 32 troubleshooting and what might be causing them. When in doubt, a local seal support systems supplier can help by providing an onsite evaluation and expert advice.

Common API Plan 32 Troubleshooting Problems

Flush Pressure

API Plan 32 requires the external flush fluid to be delivered at least 15 psi (1 bar) higher than the seal chamber pressure. If this pressure changes unexpectedly, some possible causes to look for are:

- Unexpected pressure changes upstream

- Leaks in the flush system or waterline

- Full or partial closure of the flush supply valve

- Crimped or damaged tubing supplying flush fluid to the seal chamber

- Clogged orifices or flow control valve

- Damaged or deteriorated throat bushing

Flush Flow

Changes in pressure affect flow, so follow the above troubleshooting guidelines for pressure problems first.

If pressure drop is not causing the flow problem, check the quality of the flush fluid. Plant water can contain minerals that can build up in flow control valves, obstructing flow over time. If the flush contains contaminants, they can clog flow control valves or flow meters.

If the flush fluid contains contaminants, consider preventive measures to prevent buildup. Accessible, easily maintained filters or strainers can reduce the risk of clog-related problems before they happen.

Flush Temperature

Keeping the seal chamber cool is critical to pump reliability. High temperatures will damage seals and other pump components, potentially causing a mechanical seal leak or other failures.

One of the flush fluid’s jobs is to prevent the seal faces from getting too hot. High seal chamber temperatures can be caused by insufficient flush flow or pressure. Also, check for changes or failures in upstream heat exchangers that could be causing the problem.

As for preventive measures, a temperature gauge on the tubing delivering flush to the seal chamber can identify temperature changes before they get out of control and damage the seal.

Best Practices to Improve API Plan 32 Reliability

Always follow best practices for startup, shutdown, and maintenance to protect your API Plan 32 system and prevent issues. A few best practices to keep in mind:

- Ensure the flow rate, pressure, and temperature of the flush are optimized for the pump’s standby, startup, and shutdown conditions.

- Whenever process conditions change, perform a risk assessment and make any necessary changes to the mechanical seal and seal support system.

- Schedule regular preventive maintenance to inspect seals for signs of damage or corrosion.

Of course, the best way to avoid API Plan 32 troubleshooting headaches is to start with a quality seal support system customized for your process.

Good Design Prevents API Plan 32 Troubleshooting Headaches

API Plan 32 systems are simple and reliable—when they’re designed well. A good design requires a thorough understanding of mechanical seal and throat bushing design, process fluid conditions, flush fluid conditions, and plant infrastructure.

An experienced seal support system supplier like Edmonton Valve & Fitting takes the time to consult onsite, understand your process and infrastructure, and account for any special problems or concerns you have. With this information, our Field Advisors can design and implement an API Plan 32 solution perfect for your needs.

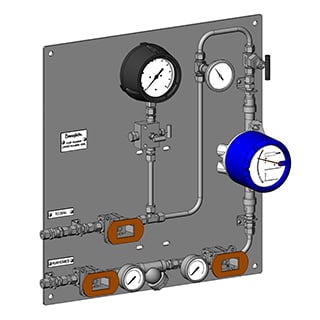

Depending on your process, some examples of custom design elements may include:

- Flow meters to monitor flush flow and alert to changes

- Pressure gauges to monitor flush source pressure

- Thermowell pre-welded into tube fitting tee to reduce leak points

- Filters or strainers to prevent clogging by flush fluid contaminants

- Check valve to prevent process fluid from infiltrating flush fluid in the event of mechanical seal failure

When problems do arise, our local experts are available to help with API Plan 32 troubleshooting, provide ongoing technical support, and ensure you’re getting optimum performance from your seal support system.

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)