Share this

Compact and Able to Handle Heat: The VB0451 Valve

by Alecia Robinson on Fri, Jun 02, 2017 @ 08:06 AM

Here's a new addition to our line of space-saving process interface valves

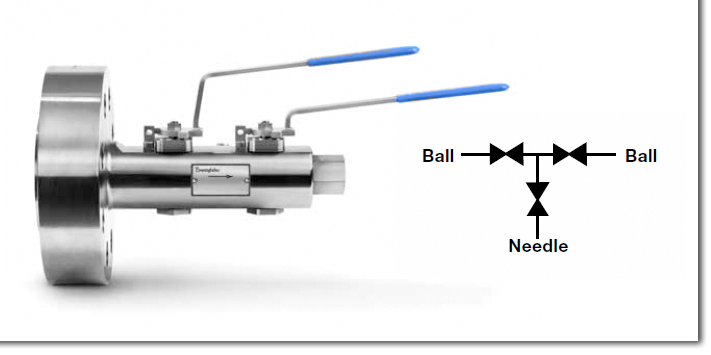

The latest addition to our double block and bleed lineup is the VB0451, pictured above. This metal-seated process interface valve allows for an extended temperature range and greater resistance to particulate containing liquids.

Over the years we've written about some of our space-saving process interface valves, from the VB03 and VB04 for ordinary service, to the VN01 for severe service.

There's one more member of the family worth mentioning, because it's a new addition to our inventory in the past year: the VB0451. It's a metal-seated process interface valve that offers an extended temperature range and greater resistance to particulate-containing liquids than standard process interface valves.

As with all of our process interface valves, the VB0451's compact size and reduced weight means that it takes up less space and requires less support structure. Because it's a single-valve unit, you can install it faster than the more traditional three-valve assembly for the same job. Having a single unit also means fewer leak points and less required maintenance.

Taking the heat

Beyond the basics, though, the VB04051 can stand up to high temperatures. Where the VB04 is rated up to only 204ºC, the VB0451 can handle temperatures up to 310ºC, and up to 280°C for duplex valve assemblies.

Swagelok tests every metal-seated process interface valve hydrostatically at the factory to a requirement of no visible leakage. A shell test is performed at 1.5 times maximum rated working pressure, and a seat test is performed at 1.1 times maximum rated working pressure. These valves are tough.

Swagelok also performs a low-pressure gas seat test, and fugitive emission testing is available on request. Metal-seated process interface valves for sour gas service are available as well.

Other features

The VB0451 valve features double block-and-bleed design in a compact ball/needle/ball configuration. The one-piece forged body is available in carbon steel, 316 stainless steel or Duplex stainless steel.

The process connections can be from half-inch to two-inch flanges, and the outlet valve is available as a flange or a half-inch female NPT connection.

A lockable handle is standard.

If you'd like to learn more, call Edmonton Valve & Fitting at 780-437-0640 or contact us through our website, and we'll be glad to answer your questions.

Additional resources

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)