Share this

Cost Saving Opportunities with Industrial Gas Delivery Systems

by Katie Reid on Wed, Feb 17, 2021 @ 14:02 PM

Let's look at opportunities to save by taking a systematic approach to distribution of industrial gases within your facility.

Many of you use compressed air, oxygen, nitrogen, and/or argon in your facilities. Use of helium, hydrogen, other gases, and special mixtures are common too. When an Edmonton Valve Field Service Technician examines a customer's gas distribution system, they often find opportunities to reduce costs and environmental impact. Then the customer gets a report (see example) detailing how to draw less energy and lower operating, maintenance, and repair costs.

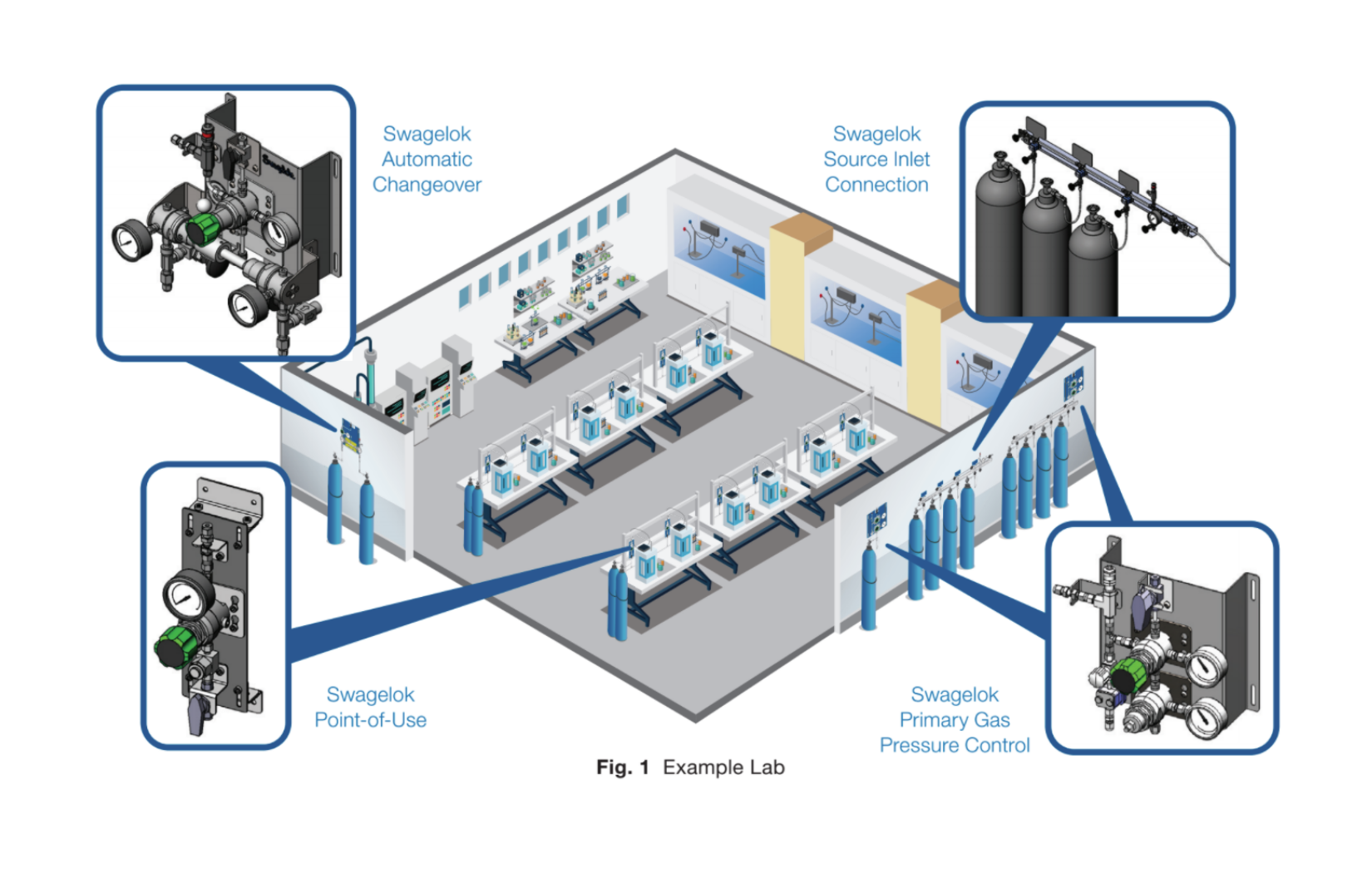

This graphic shows the four key components of a gas distribution system in an example lab. Get the guide this graphic is drawn from, here:

Gas distribution systems deliver gases from a high-pressure source to the facility at the pressure and flow rate required by each application. Doing so efficiently and safely is at the core of operations for the many oil & gas, chem refining, power, midstream, and steam-assisted gravity drainage (SAGD) companies we serve.

Nevertheless, the overall system for gas distribution is often viewed one small section at a time. (Thought experiment: if asked, could you diagram your facility's gas distribution system?)

Gas can be an expensive budget item, so leaks in gas distribution systems or unused gas in supply bottles means wasted money. Also, replacing or maintaining gas panels that leak or do not function properly use up time and money that could go into other projects.

Threaded connections are common, and often costly

Threaded connections, while a popular choice for gas distribution systems, can be prone to leakage. And as we have written before in other posts, even when the only gas involved is compressed air — a seemingly free resource — a leak still means using extra power to keep the pressure up. A leak with an orifice of only 1/16 of an inch at 100 psig will waste 280,000 cubic feet in a month.

The cost of leaks soars, of course, if a facility uses gases like helium, hydrogen, nitrogen, argon or special mixtures. Leaking connections are a very common source of fiscal losses within gas distribution systems.

The cost of not optimizing the full contents of your bottle

Another source of lost money can be not fully utilizing all the gas in your cylinders. You wouldn’t throw away a bottle of pop that is only ¾ gone, but you are doing that with your gas bottles if you aren’t optimizing the changeover point. The Swagelok SCO panel is designed to allow you to customize the changeover point to maximize the amount of gas that you use in each cylinder prior to replacing it. A Swagelok field advisor can review your current systems and help with recommendations for operating procedures and product selection that will ensure you get the most out of every cylinder.

The right components are key

Even the best maintained gas distribution systems can have issues if the correct components aren’t installed and if the system is not operated correctly. Check your system to see if there is a filter ahead of the regulator. Even ultraclean gasses can have contamination introduced to the system during cylinder changes or other maintenance processes. Adding a filter will dramatically increase the life of your regulator. That is why the Swagelok panels have filters as part of the assembly.

Another potential issue is not having the correct shut off system for the regulator. If you are currently using your regulator as a shut off point you are decreasing the life of the regulator. Adding a ¼ turn ball valve to your system will again increase the life and performance of the regulator.

A systematic approach to gas distribution

Swagelok gas distribution systems help maximize efficiency of gas usage and minimize costly leakage. Above is an overview. Assembled with leak-tight Swagelok components and tested before delivery, these systems are constructed to provide long-lasting performance while helping you reduce operating costs.

Learn more

Edmonton Valve invites you to learn about the new Swagelok Gas Distribution Program. Combining services and tailored products, it's designed to be a cost-effective way to upgrade plants' gas distribution systems. Get details here:

(Need technical help right now? Call our 24x7 Field Advisory Services On-Call Technical Support: 780-237-7109.)

Also see:

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)