Share this

Edmonton Valve’s CNC Bender Makes Quick Work of Custom Orders

by Katie Dennis on Thu, Nov 12, 2015 @ 16:11 PM

Computer controls allow creativity along with precision and fast tube bending

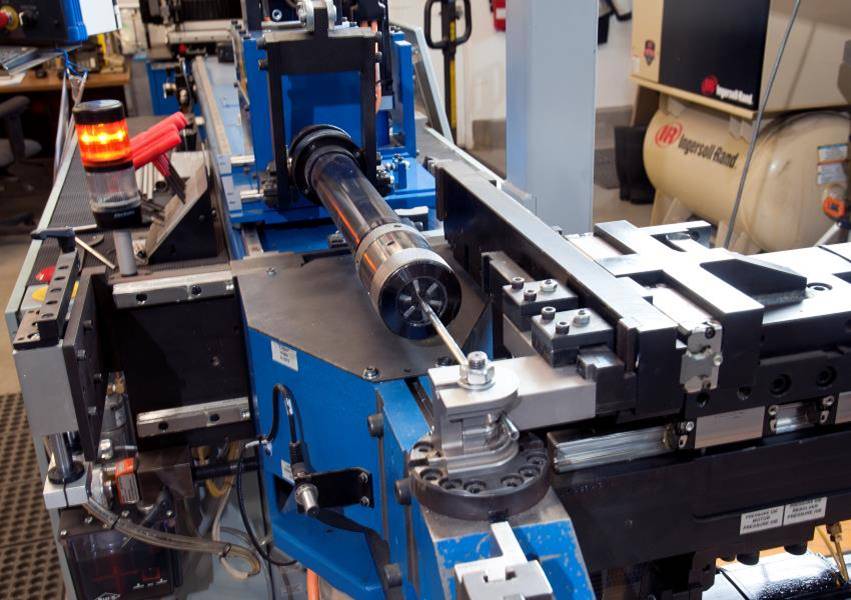

CNC Tube Bender. To learn more about Edmonton Valve's Custom Solutions department and their service offerings, download the Custom Solutions PDF here.

No matter how good you might be at bending tubing, it would be hard to outperform our CNC tube bender. It can make identical bends in hundreds of pieces of tubing, do it quickly, and remember exactly what it did the next time you put in a re-order. And that's only the beginning.

CNC stands for "computer numerical controls," the brains inside the computer that make this a precision instrument. It's a big machine, about 10 feet long, three feet high and three feet wide. That means it can handle big bends, with a radius of up to 42 inches.

The computer controls mean you get exactly the bend you ask for every time, no matter how complex the angles. That's crucial for jobs that require a lot of identical pieces. One of our customers needs a simple part involving two bends in a piece of quarter-inch tubing.

"We make 50 at a time," says Derek Green, operations coordinator for our Custom Solutions department. "If you have all the cut pieces, it takes only about 15 to 30 seconds for each piece."

Naturally, some custom orders take longer to produce than others. In most cases, though, we can turn out an order within a week. For a single part, we often can get it done the same day.

Easy adjustment

What makes our machinery especially valuable is its ability to work from an existing part rather than requiring drawings or a list of dimensions.

Say you have a piece of tubing you need to replace. We can set it in our vector machine that works with the CNC bender. The vector machine scans your part, produces a 3D drawing of it, and sends the information to the bender. When we feed in a cut piece of tubing, the bender makes an exact duplicate. It's easy to know what length of tubing to cut, because our machinery will tell us, down to a thousandth of an inch. Knowing the precise length means no wasted tubing.

Suppose you've brought in the part because it was damaged somehow. Once we've scanned in the damaged part, we can adjust the drawing to move everything into its proper alignment. We'll be glad to print out the new drawing for you.

Or, suppose the original part is fine, but you need a version with an extra inch of tubing somewhere. It's easy for us to adjust the dimensions on the computer. The CNC bender assigns a different part number to each version, and stores the information. That means when you come back next year for another run, we already have all the information we need to make fresh parts.

"It stores everything, and it backs up as well," Green says. " So if we lose power or lose documents on the computer, we can load it from a backup storage spot."

Take a look

Most of our customers know about CNC bender because we like to show it off on our shop tours. When customers come in for training, we'll demonstrate the machine by making a couple of sample bends.

But if you've missed out somehow, come on by. We'll be glad to show you what our CNC bender and our vector machine can do. Download the Custom Solutions PDF to see what our capabilities are.

Additional resources:

- New Apps Put Swagelok Product Information at Your Fingertips!

- Meet Edmonton Valve’s Stacey Phillips

- 5 Ways Tubing Beats Piping in Small-Bore Applications

In a hurry or have a question? Please click here to get in touch - we respond fast! Or call 780.437.0640

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (58)

- Services (40)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Tubing (24)

- Sampling (23)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (2)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (4)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (2)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)