Share this

How Custom Gas Distribution System Design and Fabrication Can Improve Efficiency in Northern Alberta Plants

by Thomas Webster on Tue, Jun 21, 2022 @ 08:06 AM

.jpg)

Fluid handling facilities depend on effective gas distribution system design to safely and efficiently deliver gases from a high-pressure source to various points of use. These gases are pressurized and can be toxic, corrosive, or flammable. So, careful design decisions are critical to avoid leakage, unplanned maintenance, and downtime, which can lead to inefficient operations or safety hazards. Here, we’ll look at some possible ways your current gas distribution system design may benefit from upgraded components, custom engineering, and ongoing support from your local vendor.

Gas Distribution System Design Basics

Gas distribution systems typically have four subsystems: the source inlet, gas panel, changeover, and point-of-use.

Swagelok Source Inlet (SSI)

The first stage of the gas distribution system design, the source inlet, connects the pressurized gas source to the rest of the system. For a single-cylinder source, it can be as simple as a hose with a cylinder connector. For multiple cylinders or bottles, the source inlet may need to be a more complex system of hoses and valves that deliver gas to the primary pressure control or changeover system.

Like the rest of the gas distribution system design, the engineering details that go into the source inlet depend on the application. Some options include:

- Isolation valves

- Vent or purge for individual lines

- Bottle identification tags

Swagelok Gas Panel (SGP)

The gas panel controls the pressure of gases being delivered and maintains the required flow rate using either a one- or two-stage regulator arrangement. As with the source inlet, the exact design specifications will depend on the gas being handled and individual process requirements.

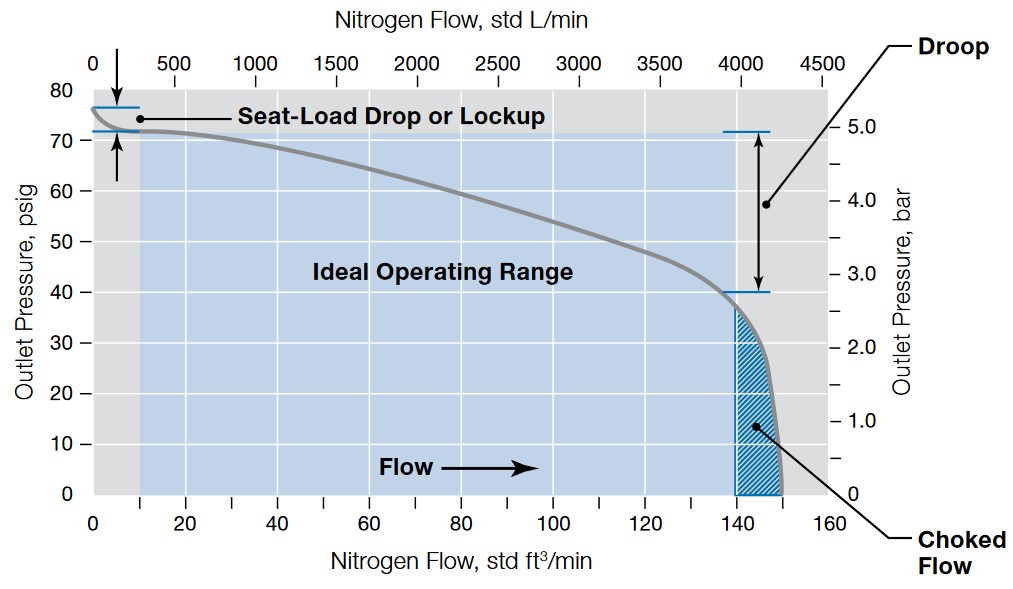

The pressure regulator is the heart of the gas distribution system, so it’s critical to select the right one for the application. Pressure regulators are selected based on a flow curve like the one shown below. Ideally, a pressure regulator should operate along the flattest part of the flow curve.

- The ideal operating range, a relatively flat part in the middle.

- The seat-load drop or lockup, where there is an initial steep pressure drop as flow begins.

- The choked-flow area, where the pressure regulator is completely open and no longer regulating pressure.

To ensure reliable and efficient service, the pressure regulator should have a filter to remove solid particles and protect the equipment. The design and material of the filter depend on the gas composition, solids content, pressure, flow, and other system characteristics.

Swagelok Changeover (SCO)

An automatic changeover system seamlessly switches from one cylinder or other gas sources to another when it reaches a set changeover pressure. This controls flow and pressure without ever interrupting the gas supply so the system can operate continuously at a constant pressure.

Changeovers can be semi- or fully automated. An automated changeover saves time and makes the process safer by eliminating human error. Additional safety options are available for hazardous or flammable gas systems.

Swagelok Point-of-Use (SPU)

The point-of-use systems where gas is dispensed are typically the least complex parts of a gas distribution system design. They provide the last stage of pressure control before the gas is used. A point-of-use station typically contains a pressure regulator, pressure gauge, and isolation valve to let operators precisely adjust the gas pressure.

The point-of-use system must provide reliable, consistent operation and be convenient and, above all, safe for the operator. Compact design and custom mounting options can help maximize space and make the system as easy and safe to use as possible.

Safety and Efficiency Design Considerations

Gas distribution systems frequently carry hazardous gases, making safety the top priority. To prevent harm to operators, equipment, and the environment, a gas distribution system design must account for any potential hazards and mitigate the risks as much as possible.

Here are a few safety considerations for any gas distribution system design:

- Reduce potential leak points by minimizing the number of connections.

- Make maintenance and troubleshooting easier by making all components and panels easy to access.

- Keep components organized and clearly label them to prevent errors.

Special Considerations for Oxygen Systems

Oxygen systems present a particularly significant fire risk. Gases or safe materials in atmospheric oxygen levels may ignite in an oxygen-enriched environment.

The “fire triangle” above shows the three elements needed to ignite a fire: oxygen, fuel, and heat. Normally, fires can be prevented by removing or limiting one or more elements, but oxygen and fuel can’t be removed from an oxygen handling system.

By making good decisions with your initial gas distribution system designs, you can improve the safety of oxygen systems by eliminating sources of heat and other hazardous conditions. Some ways to do this include:

- Avoid using stainless steel piping or tubing. Oxygen systems should be made of special materials like brass or ceramic.

- Avoid using any type of flammable oil or grease in the system.

- Use only smooth-bore tubing.

- Use only valves designed for oxygen service. While fast-acting ball valves are a good fit for most systems, they can cause pressure spikes and potentially hazardous conditions.

- Ensure pressure control valves are sized so that they can handle the system’s full range of pressures and flows.

Let the Experts Optimize Your Gas Distribution System Design

Whether you’re installing a new gas distribution system or upgrading an existing one, Edmonton Valve & Fitting is here to help. Our Field Advisors can evaluate your existing gas distribution systems and recommend quality Swagelok components that can improve safety and efficiency. We can also help engineer an optimized gas distribution system from the ground up for any gas handling application. We provide standardized, modular systems and industry-leading Swagelok components customized to your application.

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)