Share this

Why Your SAGD Grab Sampling Measurement May Not be Representative

by Tristian McCallion on Thu, Aug 12, 2021 @ 09:08 AM

Keeping SAGD process fluids at optimal conditions requires regular sampling and analysis. If the sample fluid is not representative of the process fluid, though, your grab sampling measurement won’t be useful. Inaccurate data from unrepresentative grab sampling measurements can hide potential problems that need to be addressed, keeping you from managing your fluid system proactively.

Getting a representative sample is critical to ensuring quality, efficiency, and reliability in SAGD operations, but there are many reasons this doesn’t always happen. This article will describe the most common reasons your grab sampling measurement may not be representative and how to solve or prevent each one.

Reasons Your Grab Sampling Measurement May Not Be Representative

Most cases of non-representative samples fall into one of three categories: phase changes, solids content, and inaccurate composition. Below, we’ll look at each type of problem and its possible causes in more detail.

Phase Changes

A grab sampling measurement may not be representative if the sample contains different phases than the process fluid—for example, if a liquid sample contains too much vapour, or a gas sample contains condensation.

Below are the main causes of phase changes and how to prevent them:

- Evaporation or fractionation in the sampling container: When using bottles to collect liquid samples, the liquid can evaporate or fractionate in the bottle, changing its phase composition. To prevent this, use pressurized sample cylinders (gas bombs) for sampling volatile liquids or gases.

- Vapour or condensation trapped in the container during sampling: Undesired fluid phases can also be trapped in the container while drawing the sample. This commonly happens with gases and volatile liquids. These fluids need a pressurized cylinder to draw an accurate sample. When drawing a liquid sample, the cylinder should be filled from the bottom up so any vapour is displaced through the top of the cylinder. Gas samples should fill from the top down so condensation is displaced through the bottom of the cylinder.

- Sample collected at the wrong pressure or temperature: Changes in pressure or temperature can cause phase changes in the sample. Even a small change in conditions can cause significant phase changes to a fluid close to its phase boundary. Use the P/T diagram to make sure the sampling station is set up to maintain the correct pressure and temperature to prevent phase changes.

Solids Content

In addition to vapour and condensation, solid particles can contaminate the sample—especially in SAGD operations where the process fluid tends to be heavy and dirty.

There are two common ways unwanted solids can contaminate your sample, affecting your grab sampling measurement:

- Sample taken from the bottom of the pipe: Solids suspended in the process fluid tend to settle at the bottom of the pipe, so drawing from this area can add an unrepresentative amount of these solids to the sample. Draw samples from the middle third of the pipe for the most accurate mixture of the process fluid.

- Sample taken downstream of dead legs: “Dead legs” are spaces in the system with no flow—for example, tees, pressure gauges, and temperature indicators—where solids can accumulate. Drawing samples downstream of dead legs can introduce these solids to the sample. Try to install these components downstream of the sampling station so they won’t affect sample integrity.

Inaccurate Composition

SAGD process fluids are generally mixtures of many chemicals, including hydrocarbons, bitumen, and water. If the sample is not taken correctly, the composition of these fluids can be unrepresentative of the process fluid mixture.

- Sample taken near pipe wall: Flow near the pipe wall is laminar, which can affect the mixture of the fluid’s components. Draw the sample from the turbulent flow region in the centre of the process line where it is more likely to be well-mixed.

- Sample line is contaminated: If the sample line contains traces of old fluid or contaminants, these can contaminate the sample, affecting its composition. Prevent this from happening by implementing a purge option in your sampling system. There are also continuous flow options that keep fresh process fluid moving through the sampling lines and cylinder at all times so old fluid can’t accumulate.

- Container is contaminated: The container itself can contaminate the sample if it isn’t clean. Containers should be cleaned immediately after analysis, but this doesn’t always happen. Always purge containers before drawing a sample to ensure they don’t contaminate the sample.

- Sample contaminated during transit: The more time between sample collection and analysis, the greater the risk of outside contamination. Test samples as soon as possible after collecting them. For the best protection against contamination, use cylinders, not bottles.

For Grab Sampling Measurement Support, Look to Local Fluid System Experts

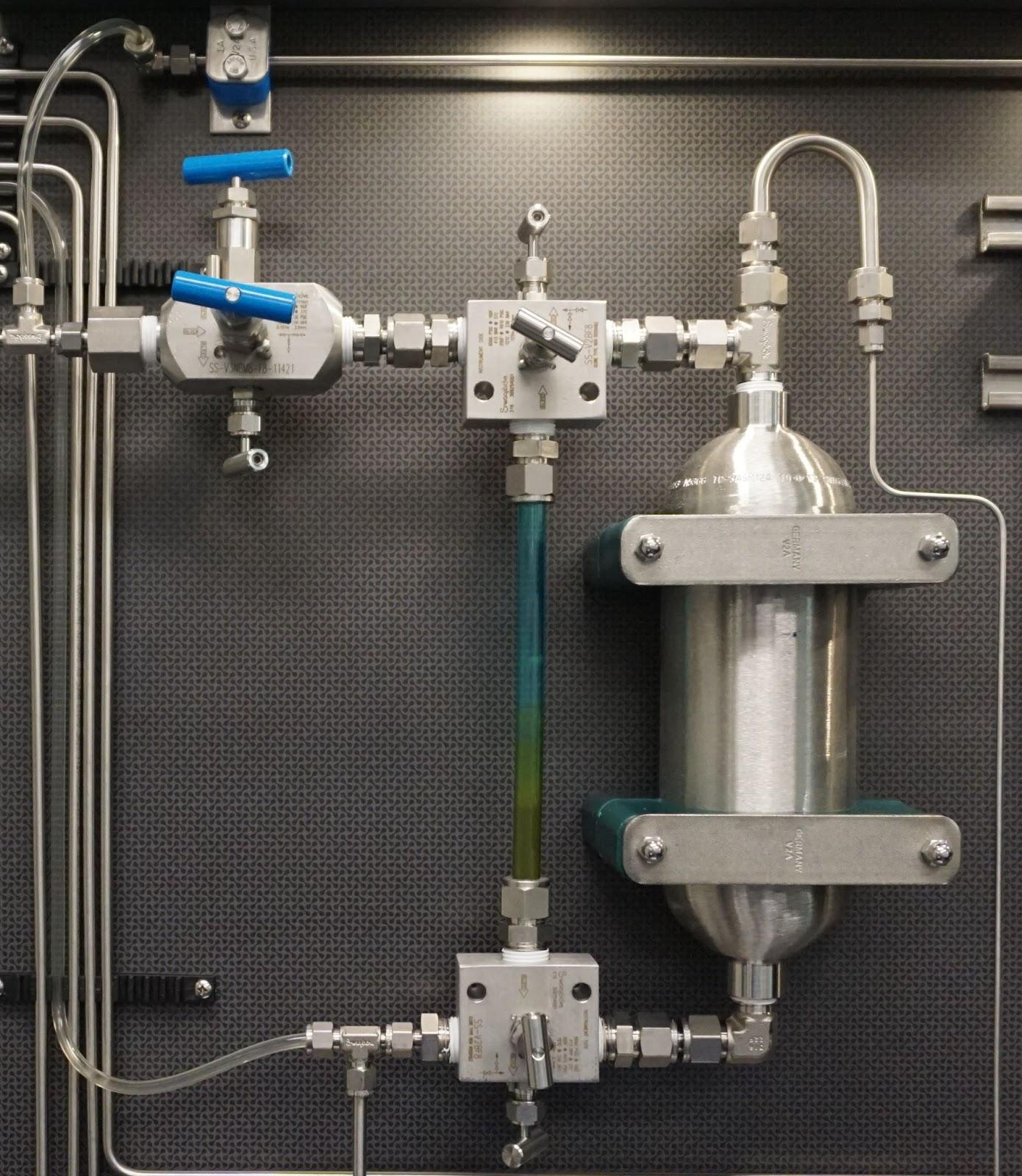

Edmonton Valve & Fitting understands the challenges of processing heavy crude oil in Alberta SAGD operations. Whether you need a new sampling system, an upgrade, or troubleshooting support, we can help. Our Field Advisors can perform a fluid systems evaluation to determine the best solution to improve performance and reliability for your SAGD operation. They can also evaluate your existing system to proactively identify potential problems before they occur and help you implement preventive measures to keep everything running smoothly.

We make grab sampling stations to order right here in Edmonton. We'll be happy to discuss your specific needs so we can help you understand the applicable industrial fluid management guidelines and make the right design choices for your SAGD operation. To help get you started, download the Grab Sampling Systems Application Guide.

About Tristian McCallion, Custom Solutions Manager, Edmonton Valve

Edmonton Valve has relied on McCallion for 26 years. His current title is Custom Solutions Manager. Earlier, he supervised our sales team. Before that, he managed sales throughout Edmonton and northeastern Alberta. For 12 years he also worked with Swagelok Energy Advisors across North America, training customers on steam fundamentals (TAP), testing steam traps, and conducting steam system audits.

Edmonton Valve has relied on McCallion for 26 years. His current title is Custom Solutions Manager. Earlier, he supervised our sales team. Before that, he managed sales throughout Edmonton and northeastern Alberta. For 12 years he also worked with Swagelok Energy Advisors across North America, training customers on steam fundamentals (TAP), testing steam traps, and conducting steam system audits.

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)