Share this

Grace Under Pressure: Swagelok's IPT Fittings

by Alecia Robinson on Tue, Jan 10, 2017 @ 09:01 AM

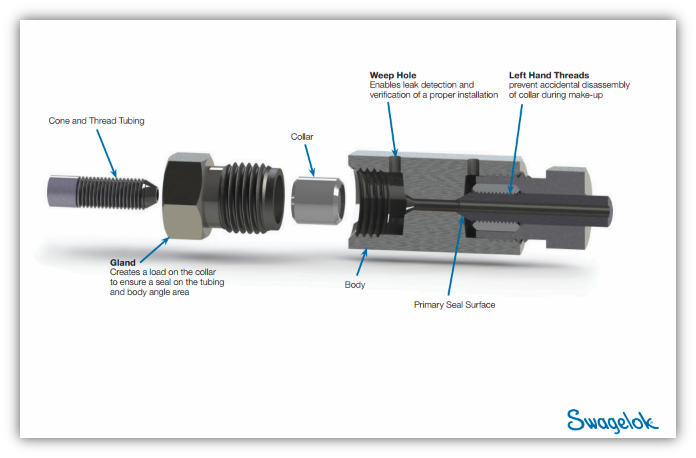

Cone-and-thread fittings make a tight, reliable seal

The image above highlights the key components of the IPT fitting.The cone and thread fittings are desgined to withstand medium and high pressure environments.

When you have a fluid system running at above-normal pressures, you need something sturdier than the standard Swagelok tube fitting. For great performance under pressure, we have the IPT series. We offer two types of IPT fittings: The medium pressure fittings are designed for up to 20,000 psig or 1378 bar and the high-pressure fittings for up to 60,000 psig or 4134 bar.

These cone-and-thread fittings are designed specifically for the oil and gas, chemical, petrochemical, water jet cutting and blasting, and aerospace industries.

A good angle

The threaded tubing ends with a cone at a 59-degree angle. It fits into the primary seal surface, which has a 60-degree angle. All manufacturers use the same interference angle between the male cone and female body, which allows for interchangeability. This is one of the rare times Swagelok gives a green light to mixing its components with those from other manufacturers.

A collar surrounds this area. A threaded part, called a gland, creates a load on the collar to ensure a seal on the tubing. This is another area where standard procedure departs from the standard Swagelok tube fitting. Instead of prescribing a fixed number of turns for proper tightening, IPT fittings require a specific amount of torque.

Another key element in IPT fittings is a weep hole at the collar. It's a quick way to detect leaks and verify proper installation. Even steam leaks are easy to spot by applying a bit of Snoop leak detector at the weep hole. When removing the collar and gland for maintenance, the weep hole also releases trapped pressure to avoid a "live loaded" thread. But never use the weep hole to bleed the system or vent system pressure. This could cause a pressure-injection injury to your employees.

The medium-pressure and high-pressure components have the same basic design, but the parts are not interchangeable. The high-pressure version has a larger collar and gland, and the collar sits inside the gland when assembled. The high-pressure design also uses thicker wall tubing to compensate for threads.

Both the medium-pressure and high-pressure versions have anti-vibration assemblies available. That's useful when the fittings are placed near a compressor, for example. Again, the assemblies are not interchangeable. An easy way to spot the high-pressure version is its additional slotted collet, which must be pointed in the right direction for assembly. (The medium-pressure slotted collet can be oriented in either direction.)

Tough tubing

The special cold-drawn tubing used with IPT fittings is also different from the standard used in other applications. It's harder and has thicker walls in order to allow cutting away material for threads with a tap-and-die set. In a sense it's really a very small pipe. We'll gladly rent you the tools to do the coning and threading, or we can do it for you if you tell us the dimensions you need.

Another difference from ordinary tubing is the outer diameter, which is slightly smaller than the nominal tube OD.

The harder steel and thicker walls also come into play when bending the tubing. The bend radius must be larger, at least 1.25 inches for quarter-inch tubing. (Keep that in mind when planning out your installation, as you'll need some extra space.) Don't try using a hand tube bender; use the bench-top version as you will also experience greater spring back.

Even extra-tough tubing is softened by heat. That means high temperatures (greater than 93.33º C) will have an impact on the pressure rating of the connection. At 204º C, the pressure rating drops to 93 percent of normal for strain-hardened 316 stainless. At 537º C it drops to 84 percent of normal.

Multiple assemblies

If you've properly installed your IPT fittings, you can take them apart and reassemble them up to five times. But it's important to make sure the cone stays perfectly smooth. If the cone doesn't fit tight against the body, you won't get a proper seal. Tubing can be re-coned if you aren't sure, though be aware that doing so can shorten the length of the tubing.

So don't let the pressure get to you the IPT download has even more information on all the types of IPT fittings and ordering information.

Additional resources

- Swagelok Orifice Fittings – What do you know about flow control?

- The Advantages of Swagelok VCR and VCO Fittings

- Don't Throw Out Those Swagelok Fittings Upon Disassembly

In a hurry or have a question? Please click here to get in touch - we respond fast!

Or call 780-437-0640

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)