Share this

How Edmonton Valve Has Brought Value and Savings to Customers Since 2000

by Katie Reid on Thu, Mar 18, 2021 @ 13:03 PM

Our 60-member + team has at least 40 ways it can add extra value for customers while doing business together. VIP Reports help customers see the total value their organization is getting from us.

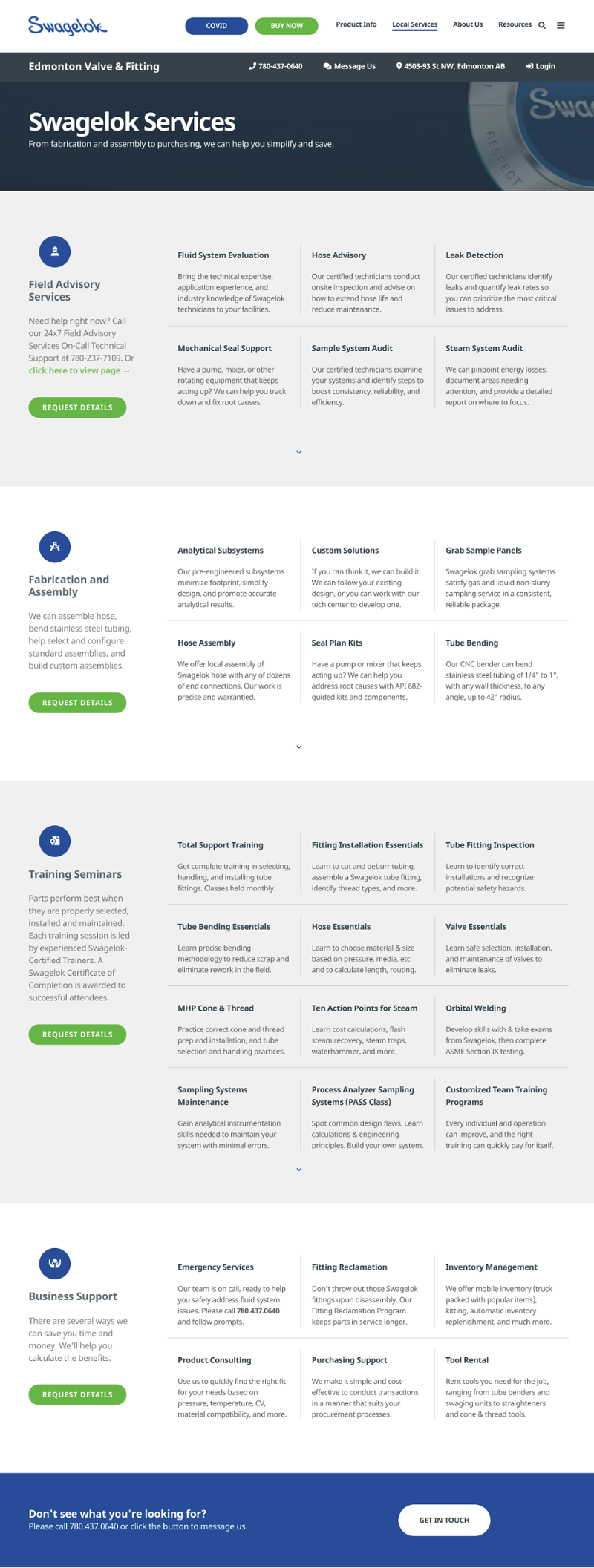

Between business support services, field advisory services, design and assembly services, and training options, there are more than 40 ways Edmonton Valve and Fitting brings customers value. At every touch point, we strive to deliver value beyond the expected -- and to track it as we go.

Throughout the year, as we interact with customers, we pay attention to ways our customers are saving time or money. That way any customer can request a VIP Report that helps quantify the benefits of the relationship.

In the case of one customer last year, cumulative savings were 48% of their total spend. The savings accrued as we took care of logistical issues; provided technical support; advised on best-value approaches to problems; uncovered ways to spend less on energy, maintenance, and components; and more.

“Usually, the more integrated our organizations are, the more ways we can add value,” explains Edmonton Valve and Fitting Business Process Manager, Brad Fedor (photo). Customers have diverse needs, and our whole team works as one to meet them.

“We might do some things for the engineering group. Something else for the warehouse logistics team on site. And then something else for the management team or an assembly group at a facility. A VIP Report is a way to summarize in one document what we are doing for the whole organization as well as for each particular group.”

Customers themselves help assign value to activities

VIP stands for Value Impact Partnership, and Edmonton Valve takes care to judge impact from the customer perspective.

“The numbers in these reports are based on more than our internal tracking of activities,” says Brad. “We ask customers what value they assign to various ways we support them. We listen very closely to understand what is most helpful, what more we might be able to do, and the like. We factor their priorities in as we help them quantify different aspects of the relationship.”

We ran hundreds of VIP reports last year, for customers large and small — and across all different industries. While savings vary from company to company, in 2020 they were typically more than 25% of what the customer spent with us.

Let's look at some of the services we provide and how customers are finding ways to save:

Mobile warehouse and replenishment

Going back and forth to will-call or waiting for deliveries can cost time and money. By making complimentary stops at customer locations with our mobile warehouse, Edmonton Valve & Fitting makes sure you get the right parts when you need them.

“We may stop by once a month to check what you need for inventory, fill an order, deliver the products, and put the inventory away on their designated shelves. This frees your warehouse staff to do other work, and eliminates freight charges,” explains Brad.

Custom solutions

If you are spending a lot of time and money assembling Swagelok parts into frequently used sub-assemblies, you can save time and money by turning the job over to our Custom Solutions Department. We have trained and certified personnel who can create assemblies specifically for your unique requirements. And it’s not uncommon for us to advise for free on whether and how custom fabrication might be of help.

Consignment inventory

Inventory can cost 15 percent to 35 percent of the average annual value of items in stock. That's a lot to pay up front. These costs include shrinkage, obsolescence, storage and the cost of money. Though consignment inventory, on the other hand, you pay as you go. The inventory stays on your premises, ready to use, but not on your books until you need it. We evaluate your current usage, set minimum and maximum inventory levels, and establish ordering procedures. This is the kind of thing we can handle for customers at no charge.

Fitting reclamation

One of the many advantages of the Swagelok two-ferrule fitting design is the ability to re-use the body without leaks. Most of the cost of replacement is in the fitting, not the ferrule. We'll show you where it makes sense in your system to re-use and refurbish. That's recycling at its best, and Swagelok has offered this fitting design for 65 years.

Product consulting

Choosing the right or wrong fluid system product can make the difference between a reliable and unreliable system. To avoid unplanned downtime and lost revenue, work with us to find the right fit for your needs based on pressure, temperature, CV, material compatibility, different types of valves or actuation, assembly, and many other factors. We can also provide expert consultation on corrosion resistance, leak mitigation, safety factors, and process and system accuracy and design.

Cutting down on leaks, waste, and inefficient design

Nothing says “you come first” as much as showing you how to spend less on components, consume less energy, and do less maintenance. And it’s not uncommon for that to be one outcome of our field advisory services.

Take design optimization, for example -- which is perfectly suited to collaborating virtually. If you share a plan, design, or list of materials with our local Field Service Technologist, Tom Webster, he may be able to streamline it so you achieve the same or better results with a smaller upfront investment and lower cost of ownership over the long term.

Fluid System Evaluation & Advisory Services and Sampling System Evaluation and Advisory Services are designed to find these kinds of savings. We take pride in looking at customers' systems as a whole, then showing precisely how to cut consumption, minimize time and money going to maintenance and repairs, make components last longer (eg extend hose life), eliminate hazards, and decrease the stock you need to keep on hand.

Clear protocols and mindfulness in every interaction

When it comes to reviewing VIP Reports with customers, we are using video meetings or phone calls instead of face to face meetings. In fact we have adapted all of our operations and services, including vendor managed inventory, to maximize safety.

“We are an essential service supplier because of what we do onsite, so for the most part vendor managed inventory has continued” despite Covid, Brad says.

The key is having a minimal footprint. There are strict protocols agreed on before Edmonton Valve sets foot on site — including how to handle at a safe distance any discussion that might be needed.

Browse services available from Edmonton Valve

"My observation is that customers we are close to — meaning our teams are intertwined — tend to operate more efficiently," explains Brad. "If we are able to learn about your pressures, priorities, and resources, you can bet we'll identify ways to add value. And you can measure the difference with an end-of-year VIP Report, which you are always welcome to proudly circulate at your organization."

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)