Share this

Considerations for Seal Flush Systems for an Industrial Fluid Oil Buffer

by Thomas Webster on Tue, Jul 20, 2021 @ 10:07 AM

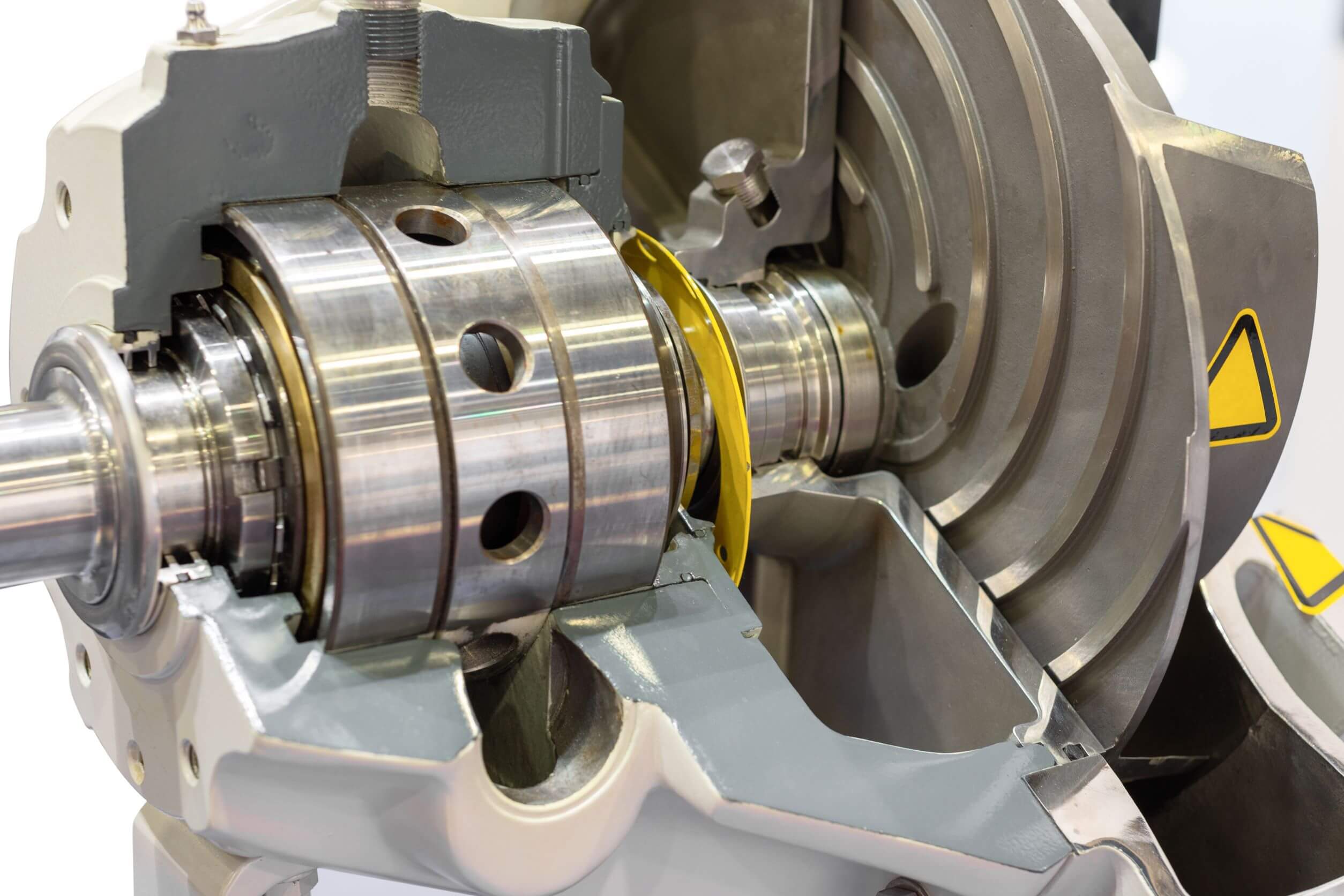

As more focus has been placed on safety, reliability, and the environmental impact of pumping equipment, dual mechanical seals have become more prevalent in industries such as chemical, petrochemical, and midstream oil and gas. Dual mechanical seals provide superior leak prevention and consist of an inboard (primary) seal and an outboard (secondary) seal. Inboard seals keep process fluid within the pump housing and outboard seals prevent buffer/barrier fluid leakage to the atmosphere. Dual mechanical seals use buffer or barrier fluid in addition to process fluid to provide lubrication and heat removal. Unpressurized dual seals use a buffer fluid to accomplish this.

For some applications, water and glycol solutions, alcohols, and kerosene and diesel fuels may not be suitable. In such cases, lube oils and synthetic lube oils are often used in seal flush systems for dual mechanical seals. Below, we will detail general considerations for oil buffer fluids as well as considerations for applicable seal flush plans for an industrial fluid oil buffer.

Industrial Fluid Oil Buffer API Seal Flush Plans

Inadequate or incorrect seal flush systems often account for a significant portion of mechanical seal failures. Dual mechanical seals require seal flush systems to provide the proper lubrication and cooling to function properly and extend seal life. For operations involving harsh process conditions, seal flush plans may require additional components, such as filters, coolers, or cyclone separators, and/or instrumentation to ensure reliable dual mechanical seal functionality. Fluid systems experts should be consulted to determine the appropriate selection of additional components for specific applications and process conditions to optimize seal flush performance.

Let’s take a look at the API plans that are suitable for oil buffer fluids.

API Plan 52: Buffer Fluid Seal Pot

API Plan 52 utilizes a reservoir and circulates unpressurized buffer fluid between the inboard and outboard seals using a pumping ring to provide positive circulation through the flush system and into the seal. Process fluid and buffer fluid must be compatible. Frictional losses in the buffer fluid inlet and outlet lines can be minimized through proper tubing size selection, use of large radii and/or 45º bends, and reduction of tube length.

provide positive circulation through the flush system and into the seal. Process fluid and buffer fluid must be compatible. Frictional losses in the buffer fluid inlet and outlet lines can be minimized through proper tubing size selection, use of large radii and/or 45º bends, and reduction of tube length.

API Plan 52 provides additional heat removal from the inboard seal when required and acts as a secondary seal to prevent process fluid from leaking into the atmosphere.

API Plan 52 considerations:

- Restriction orifice plates may be used in the vent line to maintain backpressure in the seal pot.

- Piping or tubing from the seal to the seal pot should be self-venting.

- Buffer fluid should be regularly assessed and replaced when necessary.

- Temperatures at the seal inlet and outlet line should be measured to indicate proper flow.

- Seal pot pressure and fluid level should be monitored:

- An increase in seal pot pressure or fluid level may be indicative of inboard seal leakage.

- A decrease in seal pot pressure or fluid level may be indicative of outboard seal leakage.

- Seal pot pressure should be maintained at a lower pressure than the seal chamber (and less than 40 psi).

- API Plan 52 should not be used for contaminated and polymerizing process fluid.

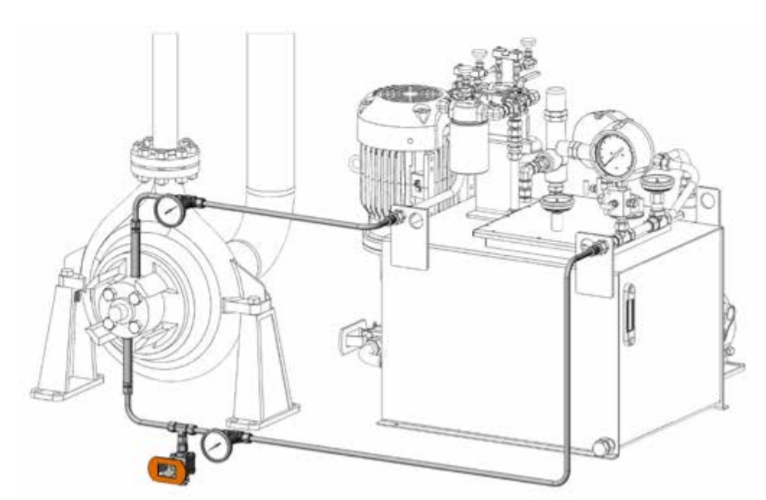

API Plan 55: Buffer Fluid Circulated by an External System

API Plan 55 is a custom-engineered system that circulates unpressurized buffer fluid to and from the seal chamber via a pump located on an external reservoir. This plan can contain additional components, such as coolers and filters, depending on application parameters and process conditions.

external reservoir. This plan can contain additional components, such as coolers and filters, depending on application parameters and process conditions.

API Plan 55 provides both cooling and lubrication to the outboard seal independent of the operation of the pump.

API Plan 55 considerations:

- Temperatures at the seal inlet and outlet line should be measured to indicate proper flow.

- Instrumentation, such as flowmeters, should be used to ensure proper flow. An increase in flow rate may be indicative of outboard seal leakage.

- Seal pot pressure should be maintained at a lower pressure than the seal chamber (and less than 40 psi).

- API Plan 55 should not be used for contaminated and polymerizing process fluid.

- Additional engineering and/or components may be required depending on the application.

Considerations for Selecting an Oil Buffer Fluid

Petroleum-based hydraulic and lubricating oils—and synthetic lubricating oils specifically formulated for buffer or barrier use—provide exceptional lubrication to mechanical seal faces, offering the potential for prolonged seal operating life. In general, oils have fewer compatibility issues with seal materials with the exception of carbon seal faces. The selection of such fluids should be determined with a mechanical seal manufacturer.

Generally speaking, an ideal buffer fluid should have the following characteristics:

- Compatibility with sealing materials and process fluid

- Safe to use, handle, and store

- Non-flammable

- Good lubrication and heat transfer characteristics

- Flows well at low temperatures

- Non-foaming or gas absorbing

- Stable at ambient temperatures

The Best Method for Seal Flush Plan Optimization

When utilizing an industrial fluid oil buffer, choosing the right seal flush plan components and instrumentation for your application is critical for mechanical seal reliability. Optimization of seal flush plans for specific applications can prevent mechanical seal failure and unnecessary rotating equipment downtime.

If you are experiencing seal flush lubrication or cooling inefficiencies or are looking to improve mechanical seal reliability, Field Advisors at Edmonton Valve & Fitting can perform a detailed on-site consultation to understand your process and recommend custom solutions, such as additional components and instrumentation, to ensure reliable and efficient rotating equipment operations.

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)