Share this

How Newer Industrial Fluid Systems Can Improve SAGD Operations

by Thomas Webster on Tue, Aug 17, 2021 @ 10:08 AM

Steam-assisted gravity drainage (SAGD) involves inherently challenging operating conditions that often impact operational performance and reliability. SAGD is an enhanced oil recovery technology used to recover bitumen from oil sands. SAGD utilizes a stacked pair of horizontal wells and an advanced form of steam stimulation to recover bitumen. Steam is injected at a high pressure and temperature of 300-340°C (572-644°F) into the top well to reduce the viscosity of the bitumen, allowing it to separate from the sand and be recovered in the form of a bitumen and condensed steam emulsion from the lower well.

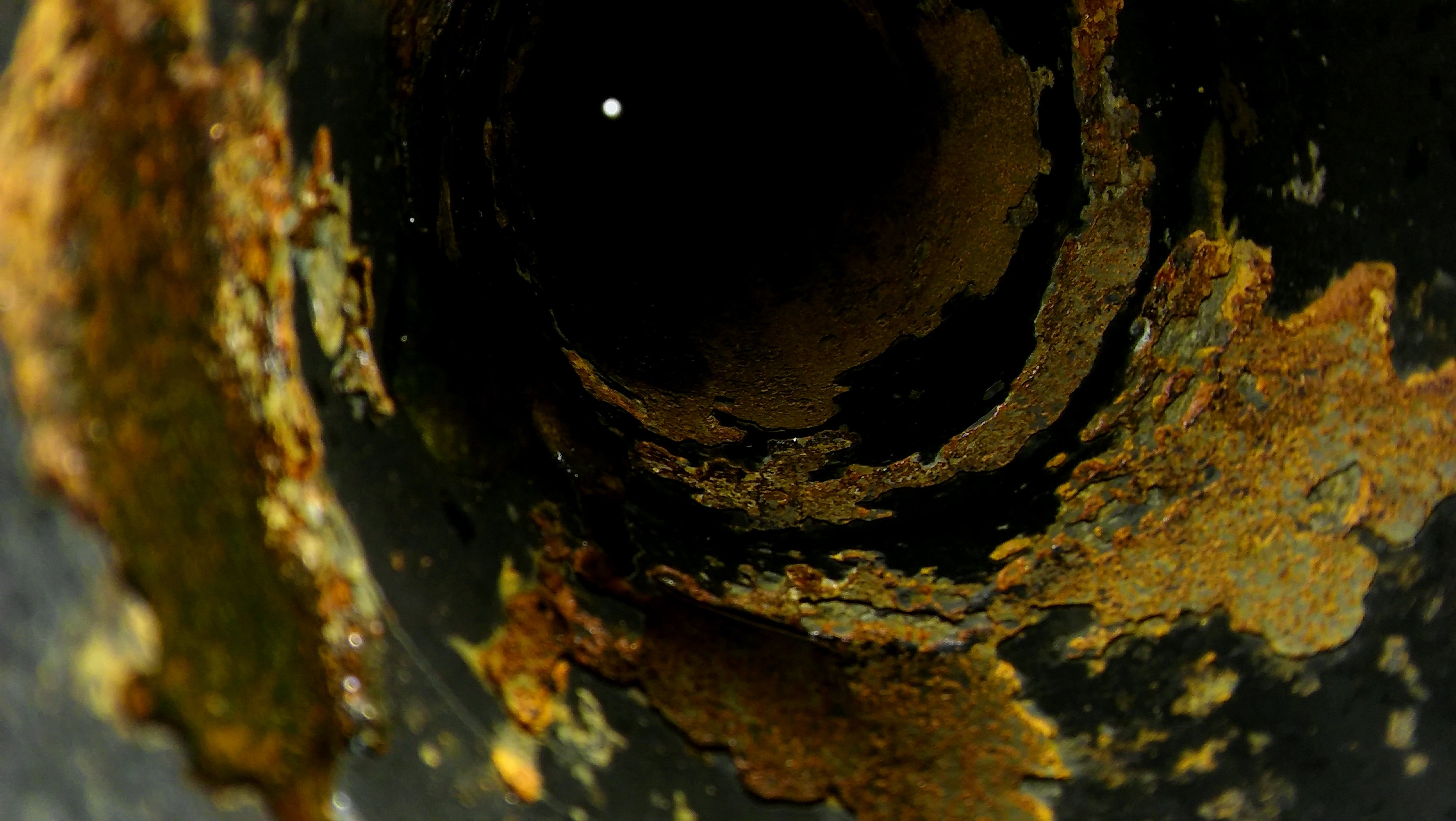

SAGD facilities in Alberta must take careful consideration when selecting industrial fluid systems to accommodate the challenging process conditions. Many units within a SAGD facility involve process conditions with high temperatures, high pressures, and the presence of hydrogen sulfide, chlorides, and total dissolved solids which can contribute to high corrosion rates.

Let’s take a look into newer industrial fluid systems and services that can aid in improving SAGD reliability.

Industrial Fluid Systems and Services to Improve SAGD Operations

The challenging process conditions involved in SAGD require careful attention and consideration when selecting industrial fluid systems, such as valves, fittings, tubing, instrumentation, sample cylinders, and sampling system components. Implementing newer technologies and services which cater to such operating conditions can reduce downtime caused by corrosion-related failures.

Robust Materials and Surface Treatments to Accommodate Harsh SAGD Operating Conditions

Common material selections, such as austenitic stainless steel, for components, tubing, sample cylinders, and instrumentation may not be suitable for SAGD process conditions and can result in high rates of corrosion and a shortened life cycle or catastrophic failure if corrosion is not caught in a timely manner. To reduce corrosion rates, materials such as 316L stainless steel or special alloys, such as the following, can be utilized:

- Alloy 400 or Monel: Often used in reducing environments, Alloy 400 is a nickel-copper alloy with excellent resistance to corrosion.

- Teflon and PFA: Teflon and PFA are often used in SAGD water treatment facilities to provide chemical resistance.

- Inconel 625: Inconel 625 is highly resistant to corrosion and is often used in oxidizing and reducing media applications.

- Hastelloys: Hastelloys, such as C-276, C-22, and B-2, offer superior resistance to pitting and crevice corrosion as well as resistance to stress corrosion cracking caused by high levels of chloride.

- ZSML Fitting: This unique coating (1035 Grade Carbon Steel, MoS2) allows the fitting to withstand temperatures of up to 427°C. It is designed specifically for Alberta’s weather conditions.

In addition to material selection, corrosion in tubing and sample cylinders can be reduced significantly through surface treatments and finishes applied to their interior surface. Coatings may also be implemented in sample cylinders to help ensure a representative sample of the process is obtained. Options include:

- PTFE Coatings: The interior surface of sample cylinders can be coated with PTFE to ensure process fluid from previous samples do not stick to the surface and contaminate future samples. PTFE coatings not only aid in ensuring a representative sample is obtained, but also greatly simplify cleaning procedures for sample cylinders.

- SilcoNert® 2000 Coatings: SilcoNert® 2000 is an inert, nonreactive silicon coating that can be used to line the interior surface of sample cylinders to provide better process control and more consistent sampling.

Improving Sampling Reliability Through SAGD-Optimized Designs and Implementations

Some industrial fluid system manufacturers may offer the ability to customize sampling systems to accommodate difficult SAGD process conditions. Beyond material selection and surface treatments and finishes, there are several customizations that can be added to sampling systems to improve sampling reliability in SAGD. For example, sample lines can be insulated and heat traced to help ensure proper flow of the process fluid to the sample point. As crude oil is highly viscous, proper considerations must be made to ensure the oil is maintained at a high enough temperature for adequate flow.

A handful of industrial fluid system manufacturers offer onsite services to evaluate sampling systems to troubleshoot problems or inefficiencies and suggest solutions that can boost overall sampling performance. Solutions may include upgrades to the sampling system or changes to the actual implementation of the system into the process.

Improving Operations Through Edmonton’s Top Industrial Fluid System Technologies Partner

Working with a local vendor who offers the flexibility to optimize industrial fluid systems for your specific SAGD operations can greatly improve overall reliability and the operational life of components and systems.

At Edmonton Valve & Fitting, we understand the unique challenges of SAGD applications. Beyond our extensive selection of high-quality components, corrosion-resistant materials, and sampling systems, we also offer expert Field Advisory services to provide onsite support and advice. Our Field Advisors can perform grab sampling audits, provide design advice, and conduct facility health checks to help address problems or inefficiencies within your SAGD operations.

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (58)

- Services (40)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Tubing (24)

- Sampling (23)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (2)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (4)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (2)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)