Share this

New Technical Briefing: Industrial Valves Guru Shares 7-Step Method for Selecting a Valve

by Katie Reid on Thu, Dec 10, 2020 @ 13:12 PM

If you don't relish valve selection, you're not alone. Here's a proven method for selecting the right valve for each application, every time.

Each design engineer, operator, or procurement expert we work with approaches valve selection a little differently. Some start by researching materials compatibility. Others start eliminating based on how difficult installation or maintenance will be; others check flow coefficient ratings, or Cv, of valves before moving on to other criteria. And so on.

None of these approaches is wrong. Still, taking a methodical approach is essential to ending up with the right valve for the job every time.

A couple of weeks ago, industrial valves guru Joe Bush presented "STAMPED Method for Valve Selection," a technical briefing where he shared a thorough, organized approach to valve selection. We recorded and posted it here:

Just below the recorded briefing you'll find resources that Edmonton Valve provided to attendees after the session.

Bush is a Senior Product Manager at Swagelok Company in Solon, Ohio. He is responsible for setting the long-term vision and strategy for the general industrial valve product line, including: ball, needle, check and relief valves as well as quick connects, and sample cylinders. In his 24 years at Swagelok, he has a wide range of experience including technical service leadership for the high purity service group, Senior Pricing Analyst, and Market Manager for Oil & Gas.

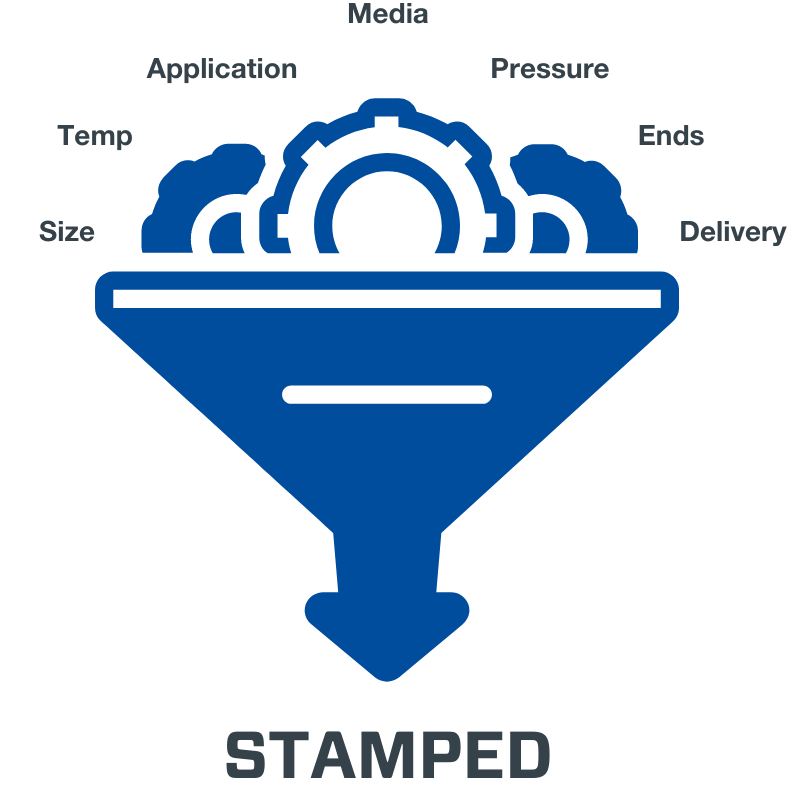

In his presentation Bush covers valve types, shows the S.T.A.M.P.E.D. method for valve selection, and answers questions from those who joined live.

The S.T.A.M.P.E.D. acronym refers to the importance of considering:

- Size (consider flow capacity and/or orifice size )

- Temperature (not only media temperature but also temperature of the environment affect temperature range needed)

- Application (consider the need for on-off isolation, flow control, directional control, pressure relief, and pressure regulation)

- Media (consider the properties of the gas or liquid it will handle)

- Pressure (consider working pressure, maximum system pressure, and whether pressure will be steady or pulsing)

- End connections (consider the range of Swagelok end connections; pipe threads are most common but there are flange, weld, and other options)

- Delivery (consider when and how many valves you need)

High temperature can soften seals, Bush points out; while low temperature can shrink seals and increase torque or cause leakage. Swagelok catalogues provide details on low/high temperature options.

Desired valve function depends on your application. Is the valve for shut-off, flow control, addressing overpressure, or something else? How will it be actuated? Customer specifications or government regulations may influence the answer. Remember too that many factors (seats, temps, frequency, cleanliness of fluid, throttling) determine cycle life.

Bush also reviews how media plays an important role, and touches on the kind of detail you can find in Swagelok’s Material Selection Guide.

Although not typically associated with construction of a valve, the end connection selection is critical to maintaining a leak-tight system, Bush says. When selecting a valve, the method by which it is installed into your fluid system will determine the type of end connection. The best choice depends in part on your priorities - like ease of installation, ensuring zero-clearance, or maximizing safety (eg weld end connections).

Swagelok valves - the big picture

As mentioned above, it's important to get valve selection right because:

The true cost of a valve is not its purchase price. The true cost is the purchase price plus the cost of owning and maintaining or replacing that valve over time.— Michael Adkins, Matching Valve Type to Function, valve-world.net

Swagelok offers ball valves, diaphragm-sealed valves, bellows-sealed valves, needle shutoff and regulating valves, manifolds, check valves, metering valves, quarter-turn plugs, bleed and purge valves, excess flow valves, relief valves, sample stream select (actuated) valves, atomic layer deposition (ALD) valves, medium and high pressure valves, and valve locks.

There is a lot of information, but we made it so you can get the whole collection of Swagelok valves literature in one step →

Talk with our Field Advisory Services team

If you have questions, please reach out to our Field Advisory team with our on-call services to lend assistance:

More about valves:

- New Full-Bore Ball Valve Handles 6000 psig + Available for Sour Gas

- FAQ: How Do I Adjust Valve Stem Packing? What About a Rebuild?

- Fluid Distribution Headers Save Space and Time

More 2020 technical briefings:

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)