Share this

Routing Hose at Manufacturing & Processing Plants: 4 Rules + Damaged Hose Photos, Video

by Katie Reid on Wed, Feb 22, 2023 @ 08:02 AM

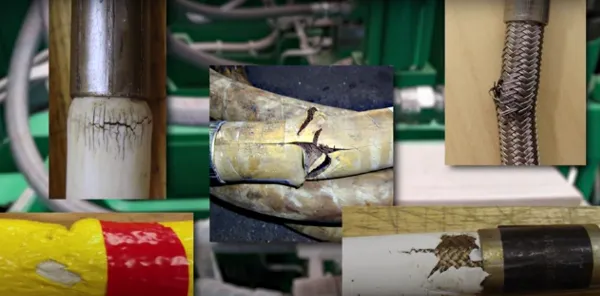

Above: A few examples of what we see in the field. See below for the video. Our Hose Resource Collection (free) delivers a range of content on this topic in one step.

Routing rigid tubing requires careful planning, but routing hose and flexible tubing is relatively effortless—right?

Wrong. In fact, Swagelok has thousands of data points showing a clear pattern: faulty hose routing is the leading cause of industrial hose failure. And short hose service life is costly in several ways. For one thing, too many manufacturers, processors, researchers, and other essential businesses overspend, year after year, on preventable hose repairs and replacements.

Correctly routing hose requires two things:

- Knowledge of best practices (see below)

- Commitment to act on the knowledge

Click above to watch Swagelok's Tech Tips video on best practices when routing and installing your hoses. To dive deeper, consider getting our Hose Resource Collection (free download).

Rule 1: Mind the bend starting point. Before starting any bends, allow a minimum straight length of hose that's at least two times the outer diameter.

The most common outcome of improper routing is kinking: the material is bent beyond its elastic limit and is permanently deformed. Installing a hose with smaller bends than advised by the manufacturer leads to shortened hose life.

Rule 2: Mind gravity. Reduce hose strain with elbows and connectors.

It's common for hoses to be installed without elbows and adapters. Those require forethought, a bit of extra installation work, and a little cost, after all. But if a hose comes out of, say, a wall or fitting horizontally, gravity will constantly pull down and bend the hose at the end connection. Over time, this can damage the hose. Elbows and adapters reduce hose strain from a connection point.

Rule 3: Mind flex. Dynamic bend radii should always be larger than static.

In dynamic applications, a hose can kink if it is too short or has been routed incorrectly. Don't underestimate the length needed. Consider the full range of motion and how system pressure changes during operation. Correct length hose distributes movement, reducing strain by preventing bends smaller than the minimum bend radius.

Rule 4: Mind twist. In dynamic applications, repeatedly bending hose on multiple planes can lead to rapid hose failure.

In static applications, hose can be bent this way and that yet have a long service life. But dynamic motion can cause repetitive twisting in one spot on the hose. That will damage the hose's core material and/or loosen its end connections. Ensure that bending occurs in only one plane by using elbows, adapters, and other methods of securing the hose.

How we can help

Hose fabrication

Our local team can build hose for you. We can combine any of 22 types of hose/flexible tubing with any of 89 end connections, in almost any length, in small or large quantities. Every hose is built and tested here in Edmonton by Swagelok-certified technicians. (Clean room assembly and custom kitting are also available.) Our Hose Resource Collection offers literature on this service.

Local, accessible hose experts

Swagelok Hose Advisors are trained to identify ways to enhance your hose selection, installation, inspection, and maintenance procedures to improve hose life and performance. We go beyond surface examinations to discover the underlying cause of failures or issues like kinking, selection, materials compatibility, length, and connectors. Our Hose Resource Collection offers literature on this service.

Hose training

Understanding the fundamentals of hose and flexible tubing helps to extend hose production cycles, promote safety, and lower total cost of ownership. Instructors introduce common terminology, explain variables impacting hose selection, and show how to select hose for different applications. Coursework includes common practices for conducting hose inspections and best practices for preventive maintenance. Please message us or call us for details.

Hose Resource Collection

This collection includes a Hose Selection & Troubleshooting Technical Briefing Video, our Hose & Flexible Tubing Quicklook, Hose Advisory Services (HAS) Literature, Locally Built Hoses: Introducing Our Hose Cell; links to articles by our local team, more technical briefings, and more.

Related content:

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)