Share this

Why a Seal Support System Water Flush Plan Matters

by Thomas Webster on Tue, May 18, 2021 @ 09:05 AM

Flush plans aim to maintain proper lubrication, temperature, pressure, and solids management by circulating fluid to or from a seal. A suitable flush plan should create an optimal working environment for the seal to prolong the seal life, avoid unnecessary wear, and prevent seal failure. Seal support system water flush plans can provide an alternative solution to flush plans involving lubrication oil, nitrogen, hydraulic oil, and other oil-based buffer or barrier fluids. Water flush plans may be implemented in cases where the process fluid is below 93.3°C (200°F) and minor dilution of the process fluid is acceptable. If the process fluid is above this temperature, a water flush plan may not be appropriate, as this runs the risk of flashing—which can lead to significant unintended consequences.

If the wrong API 682 seal support system water flush plan is implemented, this can lead to a number of inefficiencies including:

- Changes in pressure or temperature

- Vibrations

- Reduced flush flow rate

These inefficiencies can lead to unscheduled seal repair and eventually early seal failure. Luckily, there is an extensive range of API 682 seal plans available to account for any rotating equipment seal support needs in oil and gas processes.

Seal Support System Water Flush Plans Best Practices

Implementing the best practices for flush plans can greatly increase overall seal reliability and reduce flushing inefficiencies. To demonstrate the best practices for seal support system water flush plans, let’s take a look into a couple of water flush plans and the associated recommendations to improve flushing efficiency and seal reliability.

|

API 682 Plan, Location |

Description |

Best Practices |

|

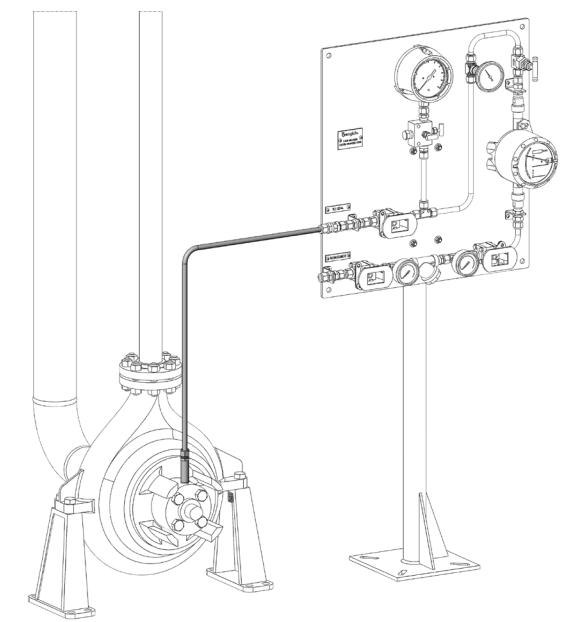

Plan 32 - Process Side

|

External Flush API 682 Plan 32 delivers a clean, cool flush fluid from an external source into the seal chamber. This plan is typically used in conjunction with a close-clearance throat bushing to maintain elevated pressure in the seal chamber. Plant water can be used as the flush fluid instead of nitrogen, but ensure it is chemically compatible with the process fluid and that dilution is not a concern. |

|

|

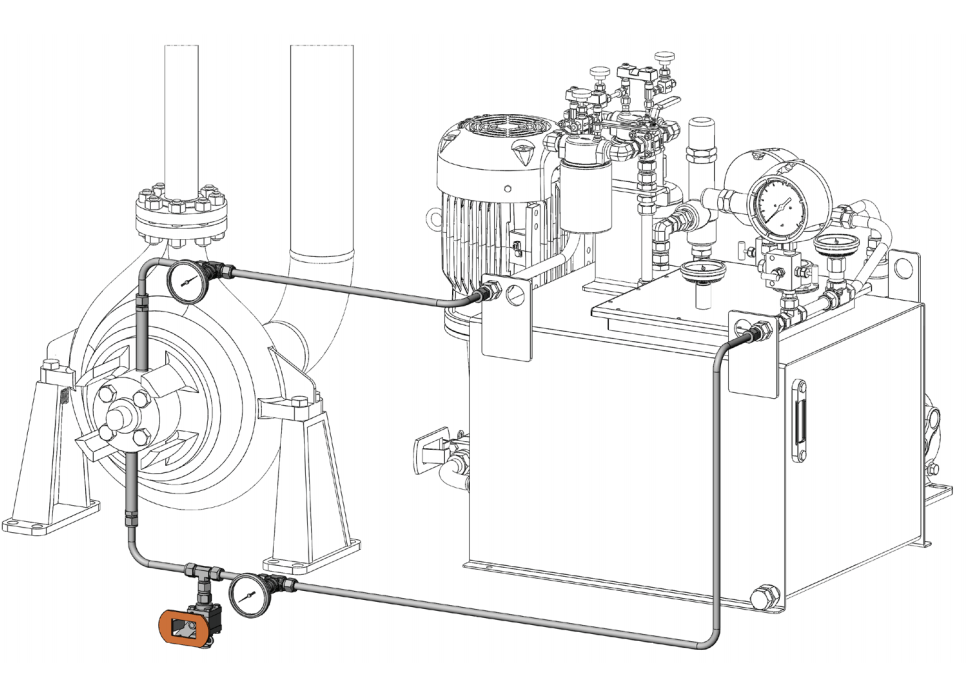

Plan 55 - Between Seal

|

Buffer Fluid Circulated by External System API 682 Plan delivers cool, clean unpressurized buffer fluid to the seal chamber that is pumped from an external reservoir. This provides cooling and lubrication to the outboard seal regardless of pump operation. |

|

|

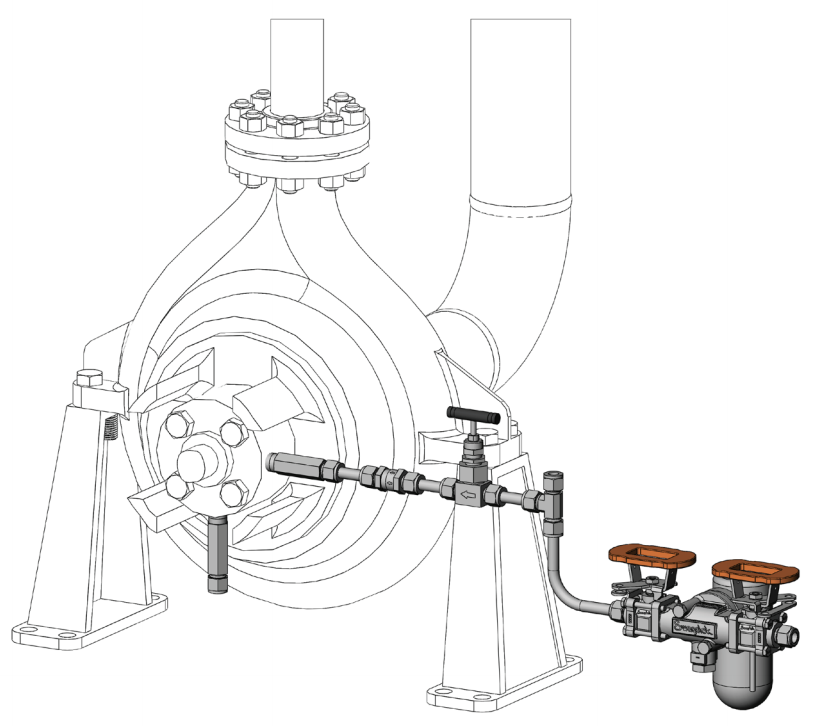

Plan 62 - Atmospheric Side

|

Quench From External Source API 682 Plan 62 delivers quench fluid from an external source to the atmospheric side of the seal. This aims to quench or cool and clean the seal surface, and can prevent coking on seal faces by clearing any solids. This plan can be used with horizontal or vertical pumps. While steam is the most common fluid in refinery applications, water and nitrogen can also be used. |

|

These are just three examples of many other water flush plans available. Each auxiliary seal plan requires careful considerations regarding process fluid and process conditions to best integrate a water flush plan into a given process. There is a significant benefit in consulting with seal support system experts to get the most out of a water flush plan.

The Benefit of Local Experts

If you are experiencing inefficiencies with your flush plan, whether that be pressure or temperature changes, vibrations, or lower flow rates, you may want to reconsider your API 682 flush plan. Having the right seal support system water flush plan can prevent unplanned mechanical seal maintenance and unplanned downtime by providing the seal with the ideal environment for efficiency.

Given the variety of seal support applications in oil and gas, there are a multitude of variables that come into play when choosing a seal support system flush plan. It is crucial to work with local experts who understand the ins and outs of flushing applications.

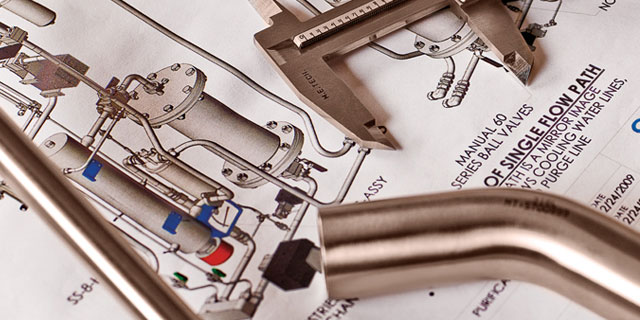

Edmonton Valve & Fitting is equipped with expert local Field Advisors who have on-the-ground experience identifying inefficiencies and recommending solutions. We can help you choose a flush plan that will maximize flushing efficiency as well as prevent unplanned seal maintenance or repair. We can provide locally fabricated, custom-configured sealing solutions that meet your requirements.

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)