Share this

Swagelok’s Field Station Modules Are Compact and Ready to Go

by Katie Reid on Thu, May 28, 2015 @ 14:05 PM

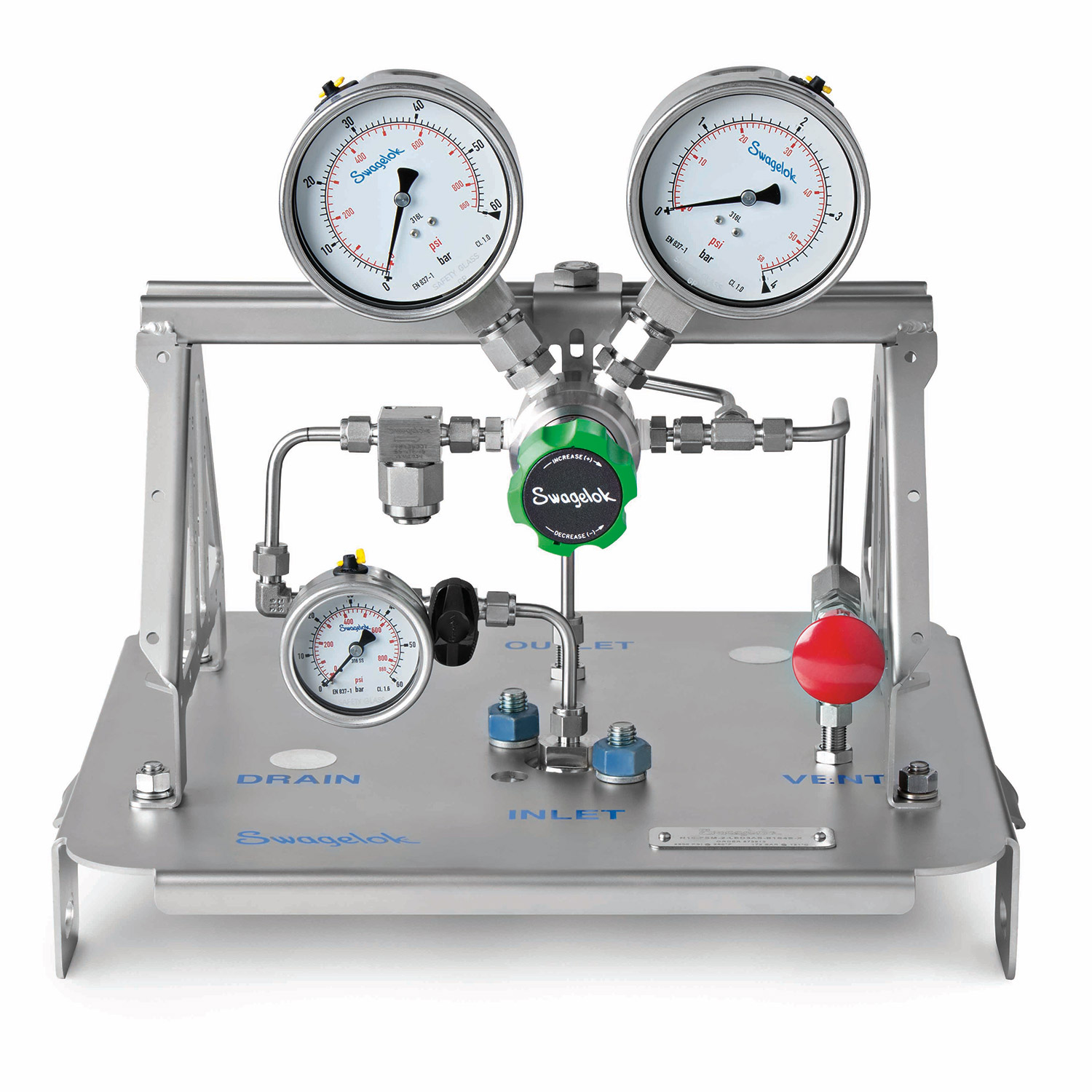

This pre-engineered subsystem moves samples to the analyzer faster

Swagelok's Field Station Module is one of our 5 Pre-Engineered Subsystem modules. To get more information on this specific design, download the free catalogue here.

When analyzing a gas sample, it's important to move the sample quickly. The rule of thumb is to get it from the process tap to the analyzer in a minute or less. One way to speed up delivery is to lower the pressure.

You read that right: Lower the pressure to speed up the sample. If that seems odd at first, think of a crowd of people trying to get onto a bus, or a large group of runners at the start of a marathon. They can't move fast because it's too crowded. The same is true of the molecules in a sample. Gas is compressible, so high-pressure lines have more gas molecules in them. By lowering the pressure, you thin out the crowd, increasing the flow rate so the molecules can get to the analyzer faster.

That's where a Swagelok field station module (FSM) comes in. When this pre-engineered subassembly is placed directly off the supply tap, it lowers the pressure of a gas as soon as possible.

In addition to giving you a fast response time, the field station module reduces condensation in the sample. Higher pressure will squeeze out any water in a gas, causing condensation issues. With a lower pressure, you don't get that change in phase.

Lower pressure also provides a safer environment for your personnel.

Flexible configurations

The basic setup is a ball valve to let the sample in, a pressure regulator, and the outlet that takes the sample down to the analyzer. You also have the option of including a relief valve so that pressure doesn't build up.

The field station module can be configured several different ways with filters. One configuration uses a small high-flow particulate filter and one or two pressure gauges, good for the lowest internal volumes and fast response times. Or you can add a pre-filter gauge if you want pressure to drop across the filter. Yet another configuration, for samples with mist in them, includes a membrane separator with a gravity drain back down the probe.

For very dirty process samples, you can configure the field station module with a large capacity particle filter. And, finally, you can include a combination coalescing/membrane filter with a drain, to get rid of both mist and particulates.

Cover up

To protect all those components, we offer several kinds of covers for the field station module: stainless steel with an optional polycarbonate window, ABS plastic with an optional tempered glass window, and fiberglass with an optional acrylic window.

The environment often will dictate the selection. If plastics aren't allowed, for instance, steel offers great protection. Steel doesn't offer much insulation against the cold, so fiberglass might be a better pick in some cases. We offer heaters for the enclosures as well.

Why do it yourself?

One of the best parts of all our pre-engineered subsystems is that they come ready to plug in and play. Your staff won't have to set aside their regular work to figure out a design, plumb in a regulator or bend tubing. You don't need to build an inventory of components, or figure out what to do with the parts that don’t conform to specs. And the assemblies come with Swagelok’s expertise, service and support behind them.

For more details, including photos and dimensions, download Swagelok's application guide here.

Additional resources

- Swagelok Sample Probe Modules: Welded Or Retractable?

- These Swagelok Valves Get the Job Done Without Packing

- Looking for a Post About Swagelok Fittings? Start Here!

In a hurry or have a question? Please click here to get in touch - we respond fast! Or call 780.437.0640

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)