Share this

Tube Bending 101: Distance Between Bends Matters

by James Dickie on Thu, Aug 04, 2022 @ 13:08 PM

Tube bending is an essential day-to-day operation in all kinds of industrial facilities. Despite its importance, tubing systems are often constructed by trial and error with little or no planning, which inevitably leads to wasted time and material and can even affect their efficiency and safety.

Fortunately, it doesn’t take any special training or complicated math to design and build a tubing system that’s optimized for the space. However, there are some important considerations when doing any kind of tube bending:

- distance between bends

- tubing length

- number of fittings

- locations of bends and fittings

These all need to be incorporated into the design before you start.

In this post, we discuss some best practices when planning out a tubing system layout, including how to determine the distance between bends.

Plan Your Tubing Layout Before Bending

Before you start any tube bending, it’s important to plan how the system will be routed. Don’t skip this step—a little planning up front can save a lot of time, effort, and money.

Create a diagram laying out all the required directional changes, taking into account any obstacles in the space and any components that need to be installed. These will be accomplished either with bends or by connecting separate lengths of tubing with fittings, depending on the situation. The system should be as simple as possible while avoiding obstacles and remaining accessible for maintenance. A logical, efficient layout will make the system easier to maintain and minimize the risk of potential problems.

Planning out an efficient design up front doesn’t just reduce material costs and produce a more attractive design—it can improve the system’s performance and lifespan. Too many multi-radius bends produce turbulent flow, which can disrupt flow and produce vibrations that can lead to premature failure.

Tubing System Design Best Practices

When planning the layout of a tubing system, there are several factors to consider. Here are some best practices to keep in mind:

- Determine the number of fittings and length of tubing required before doing any bending or installation. Make sure to allow enough tubing to seat fully into any fittings.

- Locate connections where they can be easily accessed for ease of maintenance.

- Make sure tubing does not obstruct other equipment or instrument panels, which can make them difficult to access and cause potential safety concerns.

- Avoid running tubing at handrail or footrail heights to prevent inadvertent contact from plant personnel.

- Provide support for longer runs of tubing to reduce vibration and increase the system’s life.

The Manufacturers Standardization Society (MSS) of the Valve and Fittings Industry Suggested Spacing for Supports

|

Tubing Diameter |

Tubing Diameter |

Distance between Clamps (ft.) |

Distance between Clamps (m) |

|

3/16 to 3/8 |

4 to 10 |

3 |

0.9 |

|

1/2 to 7/8 |

15 to 22 |

5 |

1.5 |

|

1 to 1 1/4 |

25 to 30 |

7 |

2.1 |

Maximum Horizontal Pipe Hanger and Support Spacing

Nominal Pipe or Tube Size (in) |

Nominal Pipe or Tube Size (mm) |

Standard Wt. Steel Pipe |

Copper Tube |

||||||

|

Water Service (ft) |

Water Service (m) |

Vapor Service (ft) |

Vapor Service (m) |

Water Service (ft) |

Water Service (m) |

Vapor Service (ft) |

Vapor Service (m) |

||

|

1/4 |

6 |

7 |

2.1 |

8 |

2.4 |

5 |

1.5 |

5 |

1.5 |

|

3/8 |

10 |

7 |

2.1 |

8 |

2.4 |

5 |

1.5 |

6 |

1.8 |

|

1/2 |

15 |

7 |

2.1 |

8 |

2.4 |

5 |

1.5 |

6 |

1.8 |

|

3/4 |

20 |

7 |

2.1 |

9 |

2.7 |

5 |

1.5 |

7 |

2.1 |

|

1 |

25 |

7 |

2.1 |

9 |

2.7 |

6 |

1.8 |

8 |

2.4 |

|

1 1/4 |

32 |

7 |

2.1 |

9 |

2.7 |

7 |

2.1 |

9 |

2.7 |

|

1 1/2 |

40 |

9 |

2.7 |

12 |

3.6 |

8 |

2.4 |

10 |

3.0 |

|

2 |

50 |

10 |

3.0 |

13 |

3.9 |

8 |

2.4 |

11 |

3.3 |

For more recommendations for tubing support, download Swagelok’s Tube Fitter's Manual. If you run into any issues during planning, contacting an expert may be your best option

Tube Bending: Distance Between Bends

Another critical factor when tube bending is the distance between bends or the amount of straight tube between bends. Why is the distance between bends important? Tube benders require a straight section of tube to clamp the workpiece securely during the bending operation. There must be a sufficient amount of tubing material for the tool to grip to prevent the tube from slipping during the operation. Having adequate distance between bends also allows bending with lower pressure, prolonging tool life.

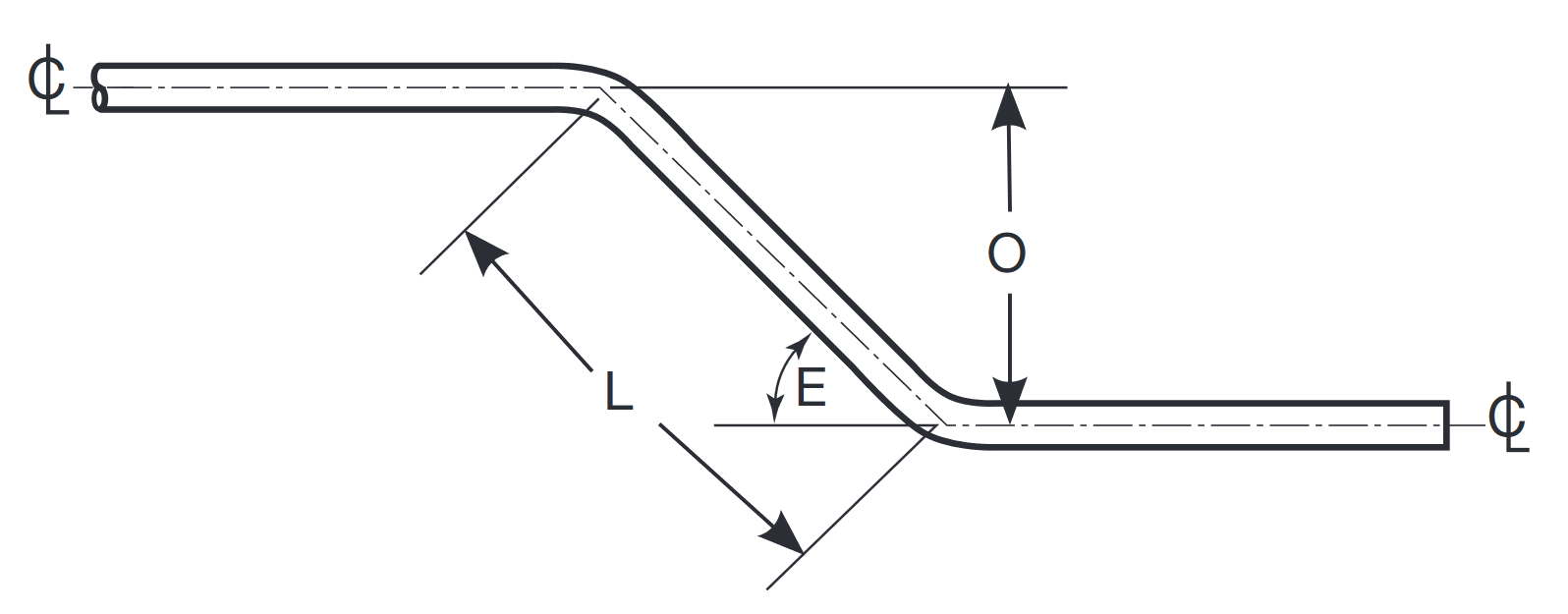

Offset Bends

Creating offset bends is a common operation in tube bending. Distance between bends is important here to ensure the offset provides the clearance needed to avoid an obstacle.

To determine the required distance between offset bends, first, use the offset angle (E) to determine the offset bend allowance (A) using the table below. Then, multiply the offset dimension (O) by the offset bend allowance (A) to get the offset distance (L).

L = O × A

|

Offset Bend Angle (E) |

Offset Bend Allowance (A) |

|

22.5° |

2.613 |

|

30° |

2.000 |

|

45° |

1.414 |

|

60° |

1.154 |

Quality Tubing Systems Start with a Quality Vendor

There’s a lot that goes into good tube bending—distance between bends is just one example of the factors you need to account for when planning and installing a tubing system. Edmonton Valve & Fitting supplies both tube benders and high-quality tubing to help you get the perfect bend every time. Need help achieving accurate bend angles or identifying defects? Our Swagelok-certified tube bending training can help your team perfect their technique and design, install, and maintain even the most complex tubing systems.

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (58)

- Services (40)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Tubing (24)

- Sampling (23)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (2)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (4)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (2)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)