Share this

Top Tube Bending Experts in Edmonton Rely on Leading-edge Tools

by James Dickie on Mon, Aug 15, 2022 @ 10:08 AM

Properly implemented tubing plays a vital role in industrial plants and facilities. Tube configuration influences the flow and pressure of gasses and liquids being moved through the tubing. Tubing also supports the overall infrastructure. It is no surprise that tubing needs to be properly bent to have tubing at the correct angles without creating weak or thin sections of the tube wall. This is all while considering what substances will be going through the tubing and how the tube will be used (e.g., in a high-pressure or low-pressure situation).

Poorly bent tubing can cause a range of issues that may result in plant shutdown or machine component failure. Tube bending needs to be done properly and with many facility characteristics in mind, but what are the best tools to achieve this tube bending, how should these tube bending tools be used, and when should these tools be used?

This article will discuss leading-edge tube bending tools, how to use them, and when. It will also discuss the characteristics and common problems of each type of tube bending tool. Finally, this article will discuss how working with experts at Edmonton Valve & Fitting can help with determining which tool to use and how.

The Leading-Edge Tube Bending Tools

There are several leading-edge tube bending tools. Each tool has unique characteristics that make it best suited for specific situations. Selecting an inappropriate tool for the needed bending method will result in increased leakage and structural problems.

Here, we discuss these tools and how they can best benefit industrial facilities:

Hand Benders

High-quality hand benders can be used to form single, offset or other bends. Unlike other types of benders, they are extremely portable. They can be especially useful in facilities where tube bending is a common maintenance need in many locations around the facility. Further, their cost—relatively inexpensive—makes them a good option for facilities where tube bending needs are unexpected or only occurring on a few occasions.

Tubing System Design Best Practices

When planning the layout of a tubing system, there are several factors to consider. Here are some best practices to keep in mind:

Roll Benders, Angle Roll Benders, or Section Roll Benders

Roll benders (also known as angle roll benders and section roll benders) use either a two-, three-, or four-roll system to press against a tube. This allows for multiple bends to be created of different radii with variable angles. However, each tube needs to be manually processed when utilizing a roll bender, and this makes utilizing roll benders a slow process for producing multiple tubes. These machines are commonly used for construction projects and coiled tubing.

Bench Top Benders

Bench top benders are tube benders that are attached to a benchtop. Though not as portable as other tube benders, high-quality bench top benders produce accurate and repeatable bends. This is especially important in facilities where tube bends need to be the same throughout the production cycle. Bench top benders can also be used for many shapes of tubes or material such as round, flat, or square stock. Further, bench top benders are also relatively inexpensive. The bench top bender is ideal for situations where tube bending is somewhat infrequent but must be accurate and repeatable. Compared to electric or computer numerically controlled tube benders, bench top benders tend to be slower. They are also less mobile than hand benders.

Electric Benders

Electric benders provide extreme reliability and efficiency to tube bending. They do this through utilizing a motor to bend pipes. This requires less physical effort than other tube bending options for operators. Electric benders are a great choice for facilities that frequently need to bend tubes in a very accurate and repeatable manner. However, they are more expensive than other options, have limited mobility due to size (though many will have wheels attached), and have limitations due to needing a power supply to operate.

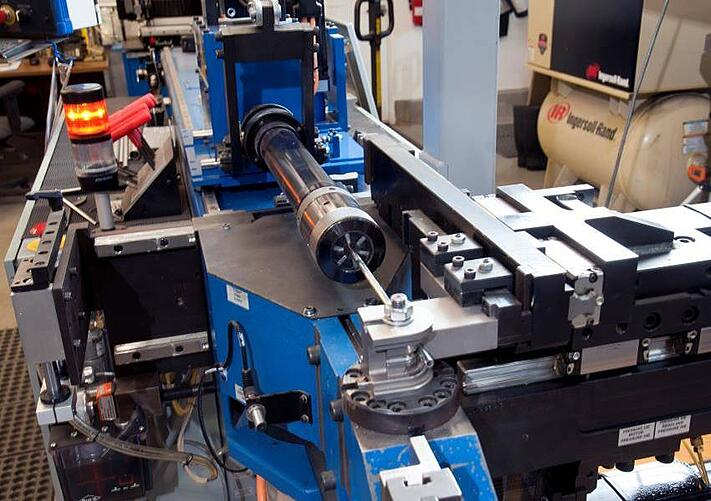

Computer Numerical Controlled Tube Benders

Automated CNC (Computer Numerically Controlled) tube bending is typically a faster, more precise, and controlled environment option than traditional hand tube bending. This method of tube bending is ideal for high volume, mass production tube bends, one-off specialty tube bends, reverse engineering tube bends, and shaping for R&D or prototyping. It helps reduce the time spent on bend projects where hand bending limits output.

Coordinate Measure Machine (CMM)

A coordinate measure machine provides extreme reliability in measurements for tube bending. These machines scan tubes and provide data to the operator through software. Data can be collected on tubes before bending, tubes after bending (to verify a successful bend or make corrections to the tube), and while tube bending occurs. A high-quality CMM is particularly useful in projects where exact and precise tube bending is essential to the fabrication process.

Tooling Station

The tooling station itself is an important component of tube bending. The tool station needs to have options for different types of material. For example, tubes composed of soft material should have a mandrel of hard material. This prevents the tubing and the mandrel from sticking together. Other aspects to consider for the area around the tooling station include having lubrication nearby to apply to tubing to prevent friction damage and the proper space around the tooling station to follow safety guidelines.

To properly utilize these tools, the needs of the facility and its tubing should be properly identified. Working with Edmonton Valve & Fitting can provide the expertise to help you select and utilize the proper tool based on your tube bending needs.

Local Tube Bending Tool Experts in Edmonton

Edmonton Valve & Fitting has the experts to help with the selection and use of leading-edge tube bending tools. We will start by taking detailed measurements to determine the flow and pressure requirements for your tubing needs. Then, we will bend the tubing and fabricate based on your specific industrial needs. We will also help implement fabricated tubing and verify proper installation.

In addition to consultation services, Edmonton Valve & Fitting also offers a CNC bender. This tool utilizes computers to exact tube bending that can be easily replicated. The CNC bender can handle any tubing from a quarter-inch diameter up to one inch and any wall thickness. It can bend any angle, even 180-degree bends. Its size allows it to handle bends with a radius of up to 42 inches. We also have the ability to verify the accuracy of bends with our in-house CMM equipment, ensuring the bend meets your precise specifications.

Edmonton Valve & Fitting can help determine what tool you need for tube bending. It can also help with the implementation of one of the most advanced tube bending tools—the Edmonton Valve CNC bender—at your facility.

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (58)

- Services (40)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Tubing (24)

- Sampling (23)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (2)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (4)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (2)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)