Share this

When Your Fast Loop Sampling System Is Not Working: A Guide to Root Cause Analysis

by Tristian McCallion on Tue, May 11, 2021 @ 10:05 AM

Fast loop sampling systems are essential during custody transfer processes. Because of the high value and large volume of the crude oil that is typically transferred, it is imperative that the sampling and measurement systems are accurate. Fast loop sampling systems are designed to handle high flow rates in sample transport pipelines to minimize time delays for online analyzer systems. High flow rates in sample transport lines are critical to providing the high velocity needed to 1) get the sample from the pipeline to the analyzer as fast as possible, and 2) maintain homogeneity of the mixture to obtain a representative sample.

If it is found that the fast loop sampling system is not working as expected, especially during a custody transfer, the issue needs to be addressed immediately. Finding an on-the-spot solution may sound like the number one priority, but it is important to understand the source of the problem to better inform future processes involving fast loop systems to keep operations running smoothly without these types of delays. If not properly addressed, these issues may persist and become progressively worse. Repeated equipment failure or malfunction can be time-consuming and costly, especially when the sampling location is remote.

Why Is Your Fast Loop Sampling System Not Working?

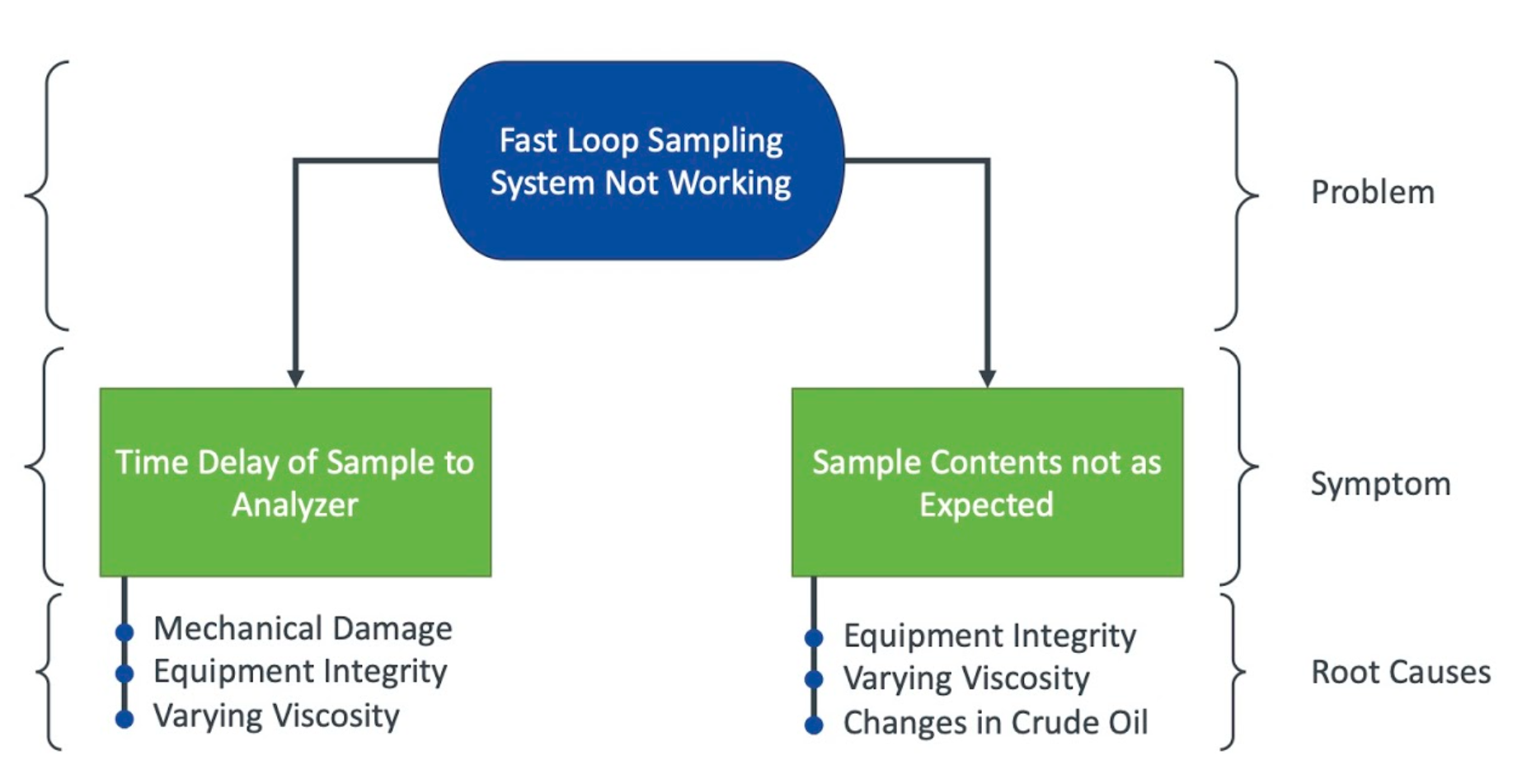

While there are many reasons why a fast loop sampling system is not working as expected, the most common issues typically occur for two reasons:

- The sample is not reaching the analyzer quickly enough.

- The contents or properties of the sample are not as expected, whether this be water percentage, chemical makeup, or variations in sediment content.

The root causes of these symptoms include changes in crude oil, varying viscosity after being upgraded, equipment integrity, and mechanical damage.

System Not Operating As per Original Design

If your fast loop sampling system is not working per its original design, the following questions should be answered:

- If it was operating well, have changes been made that affect the fast loop design that are unaccounted for? Have operating parameters changed since the original design?

- Was the original design accounting for all the operating conditions or just one specific set of parameters?

- Is the original design a good design for the particular sample required?

These can be issues for remote sampling points that get little attention. When addressed, these issues can be reviewed and recommendations made to bring the Fast Loop design up to meet current operating conditions.

Below, we detail each of these root causes and what to look for:

Changes in Crude Oil

On occasion, there can be changes in water percentage while crude oil is being handled in the oil field; though, this doesn’t necessarily mean it was handled improperly. These changes are likely to cause problems during fast loop sampling. If the crude oil’s water percentage is higher than expected, this may present an inconsistent sample makeup across multiple samples of the pipeline taken in the same location.

Changes in water percentage have the potential to cause separation within the mixture, leading to the presence of a heterogeneous mixture if process conditions are not adjusted to provide a satisfactory mixture. A process engineer will have the greatest knowledge of the process conditions and requirements regarding pressure, temperature, and flow rate to best inform the next steps.

Varying Viscosity After Upgrader

After extraction and separation, bitumen goes through an upgrader facility to be chemically modified to provide better flow. This process may involve a form of thermal processing to heat and crack the heavy oil into smaller hydrocarbons to achieve a less viscous molecule that can actually be pumped. Hydrotreating to remove sulfur and reduce the nitrogen levels may also take place during this process.

Depending on the process conditions, the crude oil may come out of the upgrader facility with varying viscosities. Higher viscosity means the fluid will move at a lower flow rate and thus, lower velocity. This could mean larger time delays from the pipeline to the analyzer. Additionally, representative samples can only be assured when there is adequate mixing by the velocity of the fluid.

Equipment Integrity

Equipment integrity depends heavily on metallurgical quality and the minimization of corrosion in piping. If inadequate metallurgical processes are implemented, corrosion rates can increase, resulting in a fast loop sampling system not working.

This is particularly problematic where dead legs exist in a fast loop system. Dead legs are inherently prone to corrosion due to the lack of flow in these regions. Corrosion can lead to leaks or even catastrophic failure if left untreated. If there is a leak in the system, the pressure and flow will be affected, potentially causing delays to the analyzer.

Mechanical Damage

Mechanical damage in a fast loop system can often go unnoticed and become a problem during these processes. It is not uncommon for operators or maintenance personnel to climb over equipment and step on tubing, though mechanical damage can be the result of any number of things. This may result in a pinch or kink in tubing, or a dent or bend in piping. In any case, this can affect the flow through the system and may delay the time between the piping and the analyzer.

Determining the root cause is never an easy task. Even if the root cause of a fast loop sampling system not working properly seems clear, the best course of action is to consult with a local expert who can work alongside a process engineer to determine the exact cause

The Best Solution for Maximizing Fast Loop Sampling Reliability

If you are experiencing problems with misrepresentative samples—and time delays with your fast loop sampling system—Edmonton Valve & Fitting offers local Field Advisory Services and 24/7 technical support to ensure the root cause is identified. Our Field Advisory experts will work with you to determine the best course of action for seamless fast loop sampling operations. Edmonton Valve & Fitting brings together global knowledge and local experience with fast loop sampling systems in oil and gas to help you solve your most difficult sampling challenges.

About Tristian McCallion, Custom Solutions Manager, Edmonton Valve

Edmonton Valve has relied on McCallion for 26 years. His current title is Custom Solutions Manager. Earlier, he supervised our sales team. Before that, he managed sales throughout Edmonton and northeastern Alberta. For 12 years he also worked with Swagelok Energy Advisors across North America, training customers on steam fundamentals (TAP), testing steam traps, and conducting steam system audits.

Edmonton Valve has relied on McCallion for 26 years. His current title is Custom Solutions Manager. Earlier, he supervised our sales team. Before that, he managed sales throughout Edmonton and northeastern Alberta. For 12 years he also worked with Swagelok Energy Advisors across North America, training customers on steam fundamentals (TAP), testing steam traps, and conducting steam system audits.

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (58)

- Services (40)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Tubing (24)

- Sampling (23)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (2)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (4)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (2)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)