Share this

Avoiding Electrostatic Discharge with Static Dissipative Hose: Photos, New Video

by Katie Reid on Wed, Mar 22, 2023 @ 08:03 AM

Steam, hydraulic oil, high velocity gases, and dielectric fluids can generate static charge when passing through a hose core. Brush up on hose selection factors that affect plant safety and efficiency.

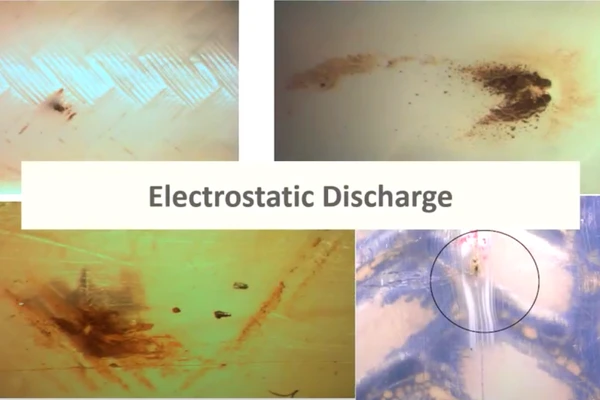

Steam and fuels can generate static charge when passing through a hose core, and these applications usually require a hose core that can effectively dissipate static buildup materials. Otherwise build up of electrostatic charge "can cause a tiny hole in the hose to develop, resulting in a hard to detect system fluid leak and providing a path for any pent-up static electricity to jump to the closest conductive material," Swagelok explains in a new video (below) which includes photos of damage that can result:

Above: Examples of damage from electrostatic discharge.

System media is a key component in proper hose selection. Identify the system media and the environment to which the hose assembly will be exposed. This will help determine the materials of construction best suited to the application demands and whether the hose requires a static dissipative core.

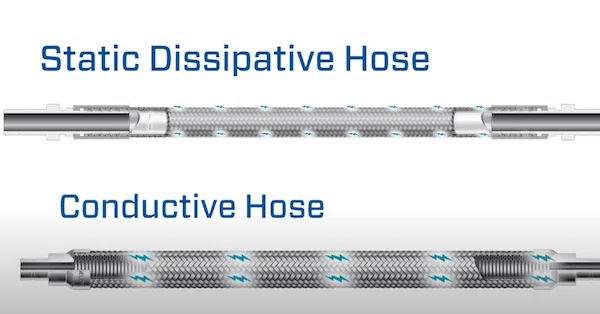

Swagelok emphasizes that conductive hose is not necessarily static dissipative, and vice versa. This video explains the difference:

Static dissipation means safely discharging static buildup, while conductivity means transmitting an electric charge. Consider our Hose Advisory service to get a hand with minimizing hose problems.

"In a static dissipative hose, it is the hose's core material that can dissipate small static charges to an area outside the hose," viewers learn. "Typically this is done by allowing the small charges to flow to the braid material and then to an end connection." An illustration:

Let's look at an example. PTFE is not a good conductor of electricity. The flow of electricity can be impeded when fluids that are good conductors, like steam or fuels, come in contact with each other. Therefore static electricity can be generated by fluid passing through the hose.

Although PTFE is non-conductive, it can be modified with sufficient conductivity to ground the static electric charge, eliminating the risk of catastrophic failure from charged particles arcing through the PTFE core. Indeed, static dissipative core tube versions are available for Swagelok PTFE hose. These conductive versions incorporate an extruded core tube of PTFE with an inner surface of carbon, often referred to as smooth-bore, carbon black-filled PTFE core. Any electrostatic charges are conducted to the end connection which are subsequently grounded.

Technicians we work with have to check, maintain, repair, and replace hundreds —or maybe thousands—of feet of hose at their facilities. With the pressure on to minimize man hours, it may seem like a safe bet to install a new version of a worn hose when replacement is necessary. But matching an older hose's features can be risky.

Analytical instrumentation equipment, for example, may have changed since the original hose was selected. Some older analytical equipment was built in a way that required a large sample of chemical or mixture to meet the requirements for a good reading. Today's more sensitive equipment can get the job done with smaller samples, but is also more susceptible to an unwanted electrical change.

It is critically important to use hose with the right static dissipative and/or conductivity properties. We offer dielectric fittings and adapters too. These types of components can additionally isolate monitoring instruments from the effects of electrical current.

How we can help

Hose Advisory Services

This service is aimed at applying Swagelok expertise to minimize your hose maintenance, repair, and replacement costs. Learn more here:

Hose Resource Collection

This collection delivers technical briefings, a quicklook sheet, relevant literature, articles by our local team, and more — all in one step. Free download here:

Hose Essentials Training

Understanding the fundamentals of hose and flexible tubing helps to extend hose production cycles, promote safety, and lower total cost of ownership. View 2023 class dates and get a free PDF with course info here:

Onsite Hose Fabrication

We build hose in our Fremont shop — sometimes with same-day turnaround. We can combine any of 22 types of hose with any of 89 end connections, in almost any length, in small or large quantities. Includes testing. Learn more:

Also see:

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (58)

- Services (40)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Tubing (24)

- Sampling (23)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (2)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (4)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (2)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)