Share this

Rely on Swagelok Seal Support Systems to Reduce Pump Failures

by Luke Wurban on Fri, Jun 12, 2020 @ 11:06 AM

When rotating equipment fails, the culprit is often a bad seal

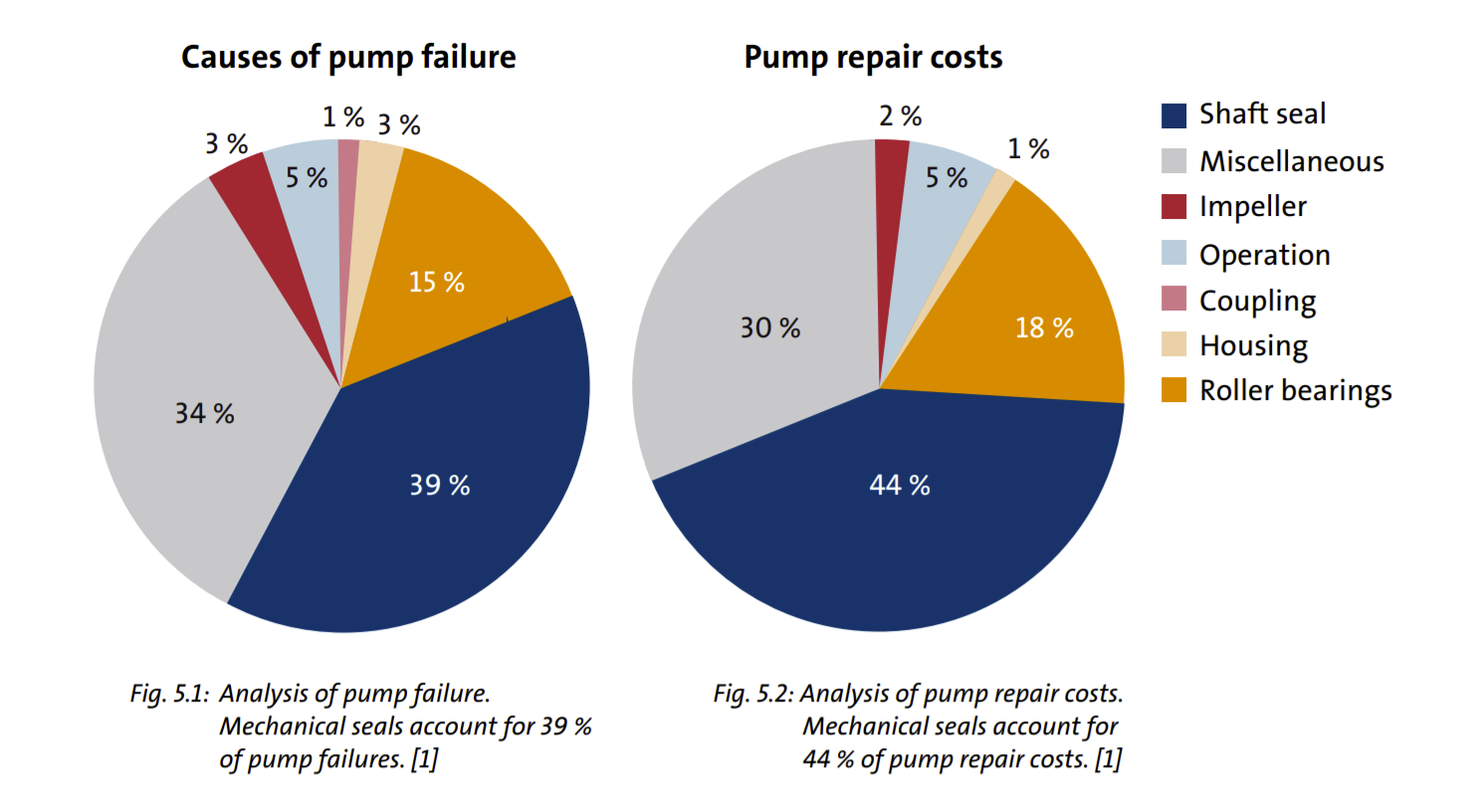

This pie chart shows how important shaft seals are for keeping pumps up and running (Photo Courtesy of Mechanical Shaft Seals for Pumps, Grundfos, page 76, http://machining.grundfos.com).

When rotating equipment fails, it’s often due to a seal failure. In fact, about 40 percent of all unscheduled critical pump shutdowns are caused by mechanical seal failures. That can get expensive fast.

Swagelok doesn't make pumps or mechanical seals, but has applied its 70 years of expertise in fluid systems to help keep your pumps up and running by eliminating leak points. With fewer leak points, systems are more reliable and cost less to monitor.

Customers asked for it

Based on customer feedback, Swagelok developed several products for its seal support systems. One is an extended metal connector, a simple fitting that allows for a one-piece transition from the connection at the mechanical seal, out past the shroud, to the tubing system.

Orifices are common installations in flush plants. Swagelok created an easy way to go from a flange to tubing with a one-piece flange adapter, incorporating the orifice right into the flange itself. That eliminates the need for one more connection or gasket to an orifice plate.

Orienting the pipe fitting for a long-stem thermometer can be an installation issue. It can require extra connections and lead to a bulky assembly. Swagelok's solution? The thermowell T. It's lightweight, compact, and welded at the factory to eliminate potential leak points.

Guided by API 682

Swagelok seal support systems are guided by API 682, incorporating all the recommended components and following best practices.

API 682 recommends specific wall thicknesses for 1/2 inch (12 mm) to 1 inch (25 mm) OD tubing. Heavier-wall tubing provides extra rigidity in high-vibration service. A heavier tube wall also creates more robust systems in areas where large pieces of equipment are being maintained and personnel may inadvertently come into contact with the tubing.

Reliability and maintainability

All of our seal support system designs focus on maintainability. For example, we used U-shaped tubes whenever possible so that components can be removed from the system without too much trouble.

Design options include high-point vents so the system can be cleared of air inclusions, which can prevent the support system from providing the desired rate of cooling.

We also put bypass lines on filters. That way, when the element needs to be cleaned out or replaced, the flow can be diverted around the filter without stopping the flow through the system.

We go beyond offering the entire seal support system, such as a seal pot on a stand. We also offer a connection kit, reducing the potential for installation errors and costly rework. They kit has a single part number, making it easy to order.

Assemblies and kits

Swagelok mechanical seal support systems are designed and built right here at Edmonton Valve, exactly how you want them and when you need them. We can design systems specific to your application, including optional isolation valves, bypass loops, and instrumentation to help you maintain the system and monitor the health of the seal.

We offer seal support systems as both kits and assemblies.

Seal plan kits contains everything needed for proper installation, including an engineered drawing. For projects or turnarounds, seal plan kits can be used to standardize how plans are connected to the pump. Kits also show technicians where to bend tubing to eliminate potential leak points through the reduction of elbow fittings and pipe threads.

Seal plan assemblies are panels, seal pots, or skid systems that comprise the majority of the API seal support plans. Seal plan assemblies can be ordered alone or with the associated field installation kit.

Support

With Swagelok Custom Solutions from Edmonton Valve we can also:

- Help source proper components

- Generate bill of materials

- Provide support from trained and certified experts

- Assist with creating CAD drawings to your application specifications

- Assist with piping and instrumentation diagrams to your requirements

- Fabricate and assemble customized API 682 systems

- Provide tube bending, welding, and other value-add services

- Provide seal plan kits that bundle plan components

- Deliver locally available critical spares

We can stock spares locally, from individual fittings to entire seal support systems. When you need them, we can deliver right away. And Swagelok products are backed by our Limited Lifetime Warranty.

Get the literature

We have several pieces of literature that go into greater detail on the subject. Our Mechanical Seal Support Systems brochure and guide show how Swagelok can help you end seal failures. We can even send you a chapter on the failure of mechanical shaft seals from the book "Mechanical Shaft Seals and Pumps."

Get all three documents, and other supporting documents here. Then call Edmonton Valve & Fitting at 780-437-0640, or drop us a note using the contact page on our website.

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)