How Reducing Fugitive Emissions with Valves Can Minimize Costs for Alberta Oil and Gas Operations

by Thomas Webster on Thu, Sep 02, 2021 @ 09:09 AM

Fugitive emissions are unintentional leaks of vapours or gases, typically methane, from pressurized equipment into the atmosphere. Oil and gas facilities have numerous potential sources of fugitive em …

Top 4 Causes of a Seal Support System Leak —And What Northern Alberta Operations Should Do

by Thomas Webster on Tue, Aug 31, 2021 @ 16:08 PM

Petrochemical refineries in Northern Alberta rely on seal support systems to keep pumps working efficiently and safely and to prevent leaks. A seal support system leak, whether slow or catastrophic, c …

Mechanical Seal Support Failure Analysis: A Guide for SAGD Operations

by Thomas Webster on Thu, Aug 26, 2021 @ 09:08 AM

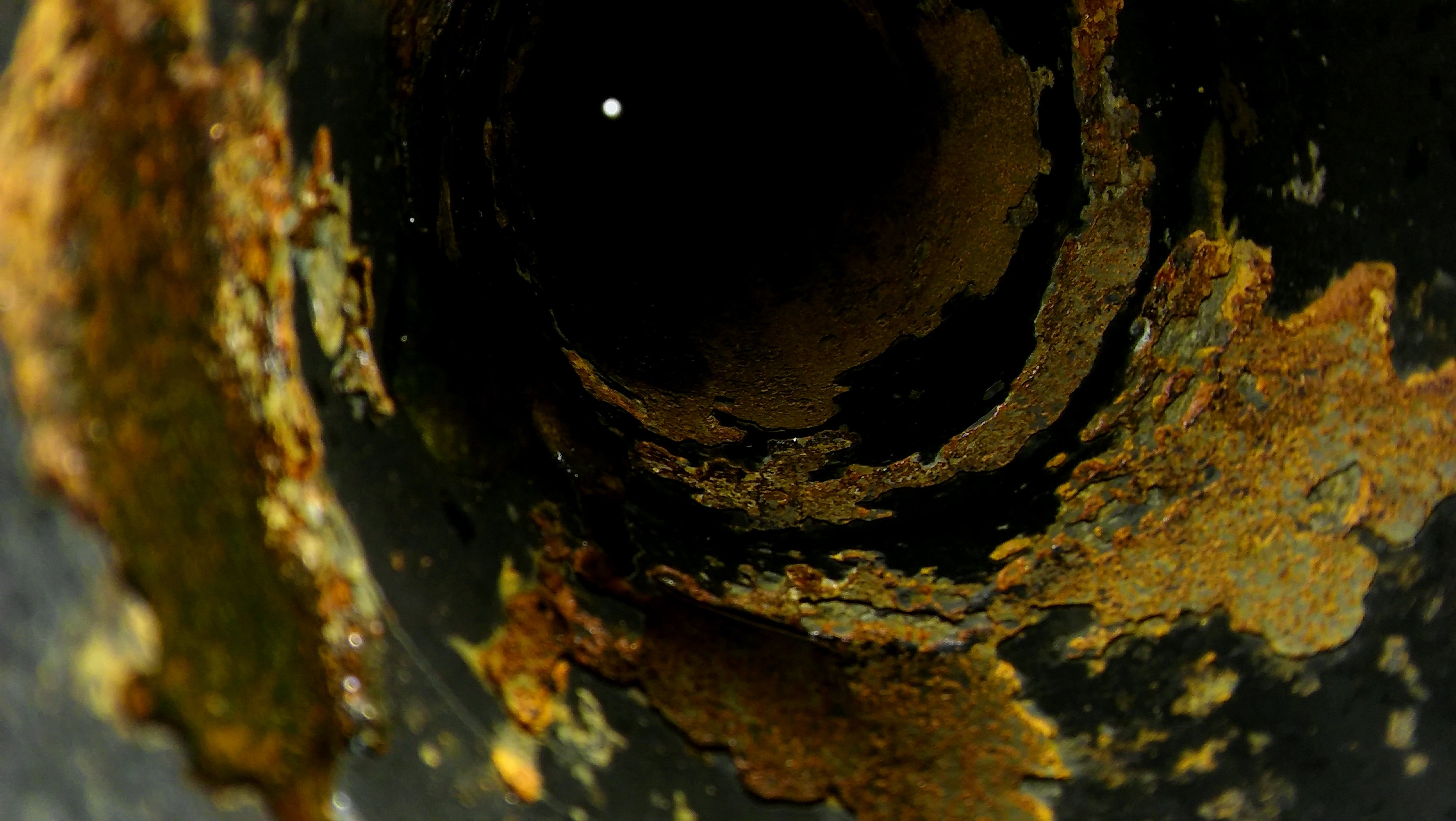

Mechanical Seal Support Failure: Pictures and Common Root Causes in Northern Alberta

by Thomas Webster on Tue, Aug 24, 2021 @ 11:08 AM

Mechanical seals keep pumps from leaking by containing pressure while protecting the seal faces from the friction of the rotating pump shaft. The seal support system allows this to happen by lubricati …

Wondering Which Seal Support Systems to Use? Options for Northern Alberta Refineries

by Tristian McCallion on Thu, Aug 19, 2021 @ 13:08 PM

Northern Alberta refineries depend on seal support systems for safe and efficient pump operation. API 682 defines a multitude of seal flush plans and their use cases—but even when you know which seal …

How Newer Industrial Fluid Systems Can Improve SAGD Operations

by Thomas Webster on Tue, Aug 17, 2021 @ 10:08 AM

Steam-assisted gravity drainage (SAGD) involves inherently challenging operating conditions that often impact operational performance and reliability. SAGD is an enhanced oil recovery technology used …