Considerations for Seal Flush Systems for an Industrial Fluid Oil Buffer

by Thomas Webster on Tue, Jul 20, 2021 @ 10:07 AM

As more focus has been placed on safety, reliability, and the environmental impact of pumping equipment, dual mechanical seals have become more prevalent in industries such as chemical, petrochemical, …

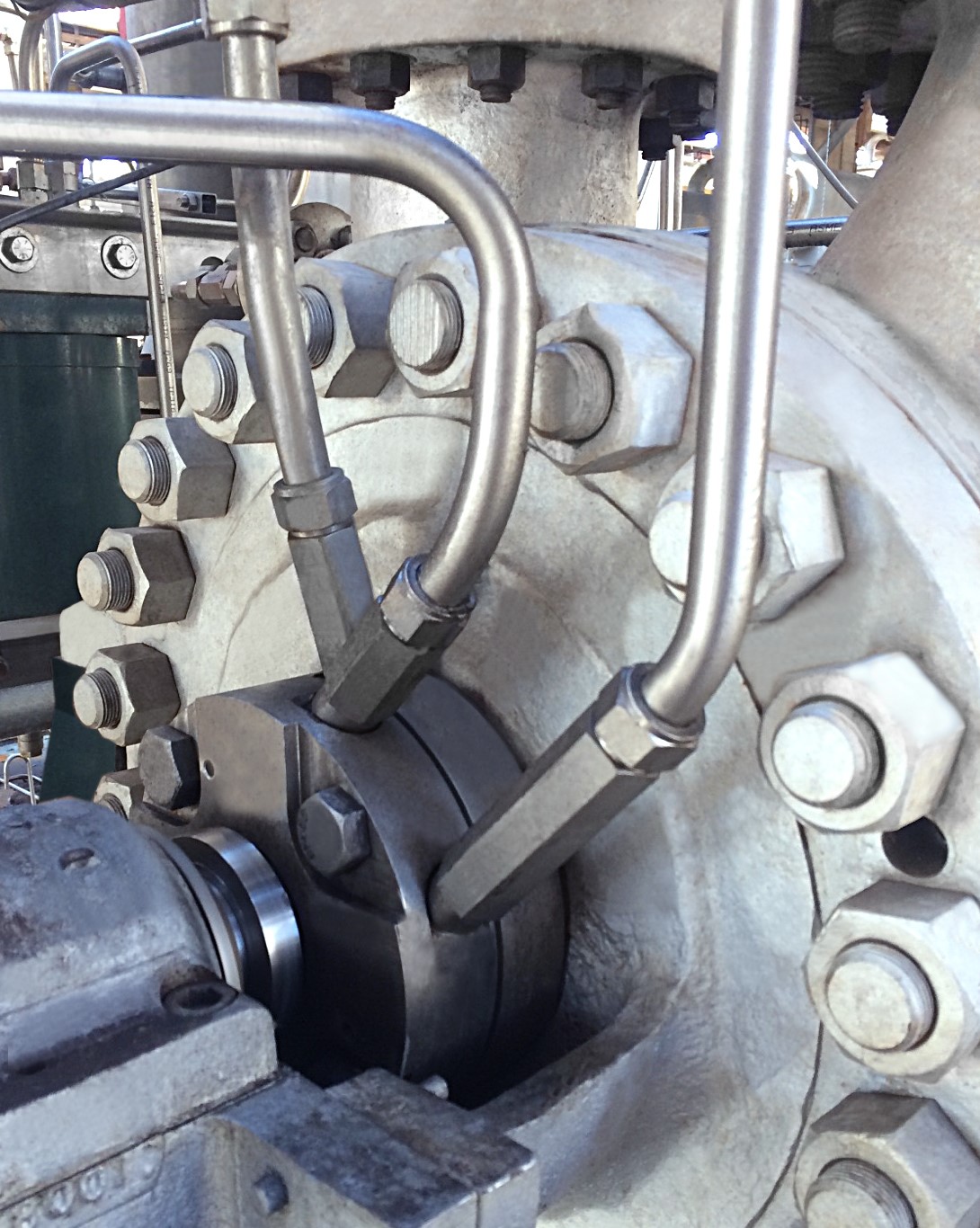

Why Plan 52 Failure Happens and How to Address it in Alberta Refineries

by Thomas Webster on Tue, Jul 13, 2021 @ 15:07 PM

Dual mechanical seals are often used in Alberta refineries when pumping applications involve hazardous fluids to provide an extra level of safety. To maintain proper lubrication and heat removal to du …

Solving Seal Flush Plan 11 Challenges More Easily for SAGD Operations

by Thomas Webster on Wed, Jul 07, 2021 @ 08:07 AM

Seal flush Plan 11 is the most common piping plan used for single mechanical seals in steam-assisted gravity drainage (SAGD) operations. It is simple, inexpensive, and recirculates process fluid from …

Understanding How the API Plan 52 Seal System Works For Canadian Operations

by Thomas Webster on Tue, Jun 29, 2021 @ 11:06 AM

Pumping processes involving hazardous or toxic fluids often utilize dual mechanical seals to ensure operator safety and compliance with environmental regulations. The American Petroleum Institute (API …

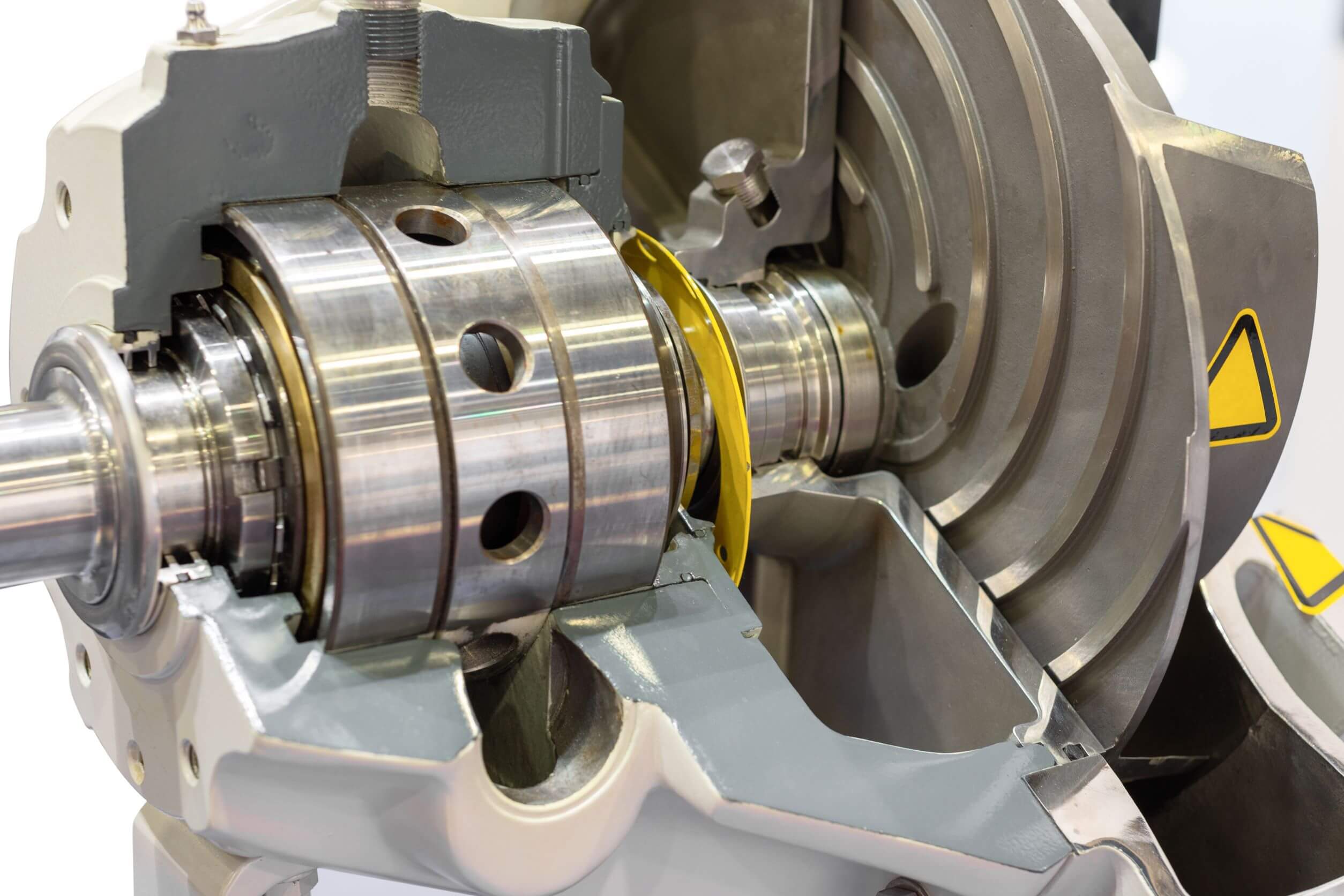

Mechanical Seal Heat Checking Solutions for SAGD Operations

by Thomas Webster on Thu, Jun 24, 2021 @ 08:06 AM

Mechanical seal heat checking is characterized by the presence of radial cracks originating from the center of metallic, tungsten carbide, or ceramic seal faces. This may appear as scoring or a checke …

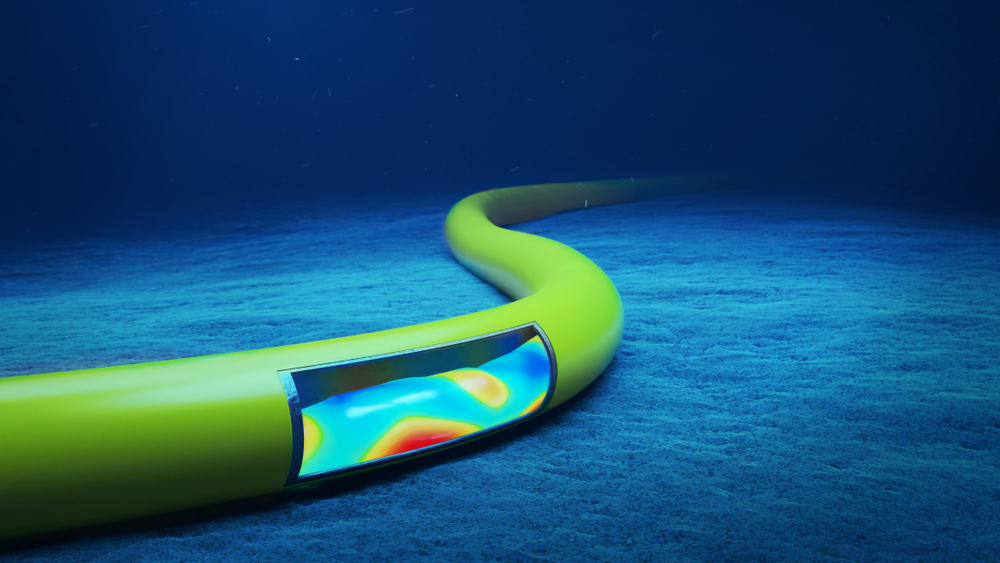

Why Flow Assurance Fluid Characterization Matters for Aging SAGD Wells

by Thomas Webster on Tue, Jun 22, 2021 @ 13:06 PM

Flow assurance fluid characterization is the concept of ensuring fluid flows effectively and efficiently from point A to point B. Originally, flow assurance was a term used to describe the analysis an …